The first Nature article in the field of 3D printing technology in 2024 was published on February 27th. A team of researchers from the Institute of Metals, Chinese Academy of Sciences (IMS) published an article titled "High fatigue resistance in a titanium alloy via near void-free 3D printing".

The article argues that the underlying 3D printed microstructures have a naturally high fatigue resistance, and that the degradation of this property may be caused by the presence of micropores. Conventional efforts to eliminate micropores often result in tissue coarsening, while the process of tissue re-refinement brings about the recurrence of porosity and even triggers new disadvantages such as the enrichment of α-phase at grain boundaries, making the microstructures dilemma of in-and-out efforts.

During the heat treatment research conducted by the CAS team, a key post-treatment process window was discovered, where the phase transition and grain growth of 3D printed titanium alloys at high temperatures are asynchronous. With sufficient superheat, the α to β phase transition occurs immediately, and although the β phase growth temperature has been reached, the grain boundaries need a gestation period to rearrange themselves. Taking advantage of this valuable heat treatment window, the researchers determined a heat treatment method combining hot isostatic pressing and high-temperature short-time treatment, which both achieved tissue refinement and prevented α-phase enrichment as well as the reappearance of micropores, and ultimately prepared near-printed state 3D printed titanium alloys that are almost free of micropores.

TC4 titanium alloys with this microstructure achieve a high fatigue limit of about 1 GPa, exceeding the fatigue resistance of all current additively manufactured and wrought titanium alloys, as well as other metallic materials.

The 2nd Nature article in the field of 3D printing technology in 2024 was published on March 13th. Building on a continuous liquid interface production technique developed at the university in 2015, researchers at Stanford University have developed a 3D printing technique for more efficient production of microscale particles, making up to 1 million micron-sized particles per day with high precision and customizability.

Nano- to micron-scale particles have a wide range of applications in biomedical devices, drug and vaccine delivery, microfluidics, and energy storage systems. However, conventional fabrication methods require balancing multiple factors such as fabrication speed and scalability with particle shape and uniformity and particle properties.

Researchers at Stanford University have developed a scalable, high-resolution r2r CLIP 3D printing process that uses single-digit micrometer resolution optics with continuous film to enable rapid, variable fabrication and harvesting of particles with a variety of materials and complex geometries. With this technology, researchers can achieve micron-level precision 3D printing while maintaining high production speeds and flexibility in material selection, opening up new possibilities for particle manufacturing.

This scalable particle production technology has been demonstrated toManufacturing potential in a wide range of fields from ceramics to hydrogel manifoldsThe research was published under the title "Roll-to-roll, high-resolution 3D printing of shape-specific particles," and subsequently has potential applications in microtooling, electronics and drug delivery. The study was published under the title "Roll-to-roll, high-resolution 3D printing of shape-specific particles".

Source: AMReference

On March 20, the Long March 8 Remote 3 Launch Vehicle (R3LV) successfully put the Magpie II satellite into the scheduled orbit. The Sixth Academy of Astronautics pointed out in a related report that "during this launch, there wereSatellite storage tank structure realized by 3D printing processThis has laid a good foundation for the mass production of microsatellites and network launching, which has significant commercial value".

On April 3, 2024, the Magpie Bridge conduction technology test satellite for the Moon Exploration Project, Tiandu-2, was separated normally in orbit, and the cold push system worked normally.Marking the first time that domestic spaceflight realizes the application of 3D printed storage tanks in orbit, laying a solid foundation for the use of 3D printing technology in space propulsion.

The tank is jointly developed by Institute 801 of the Sixth Academy of Space Science and Technology and Institute 800 of the Eighth Academy of Space Science and Technology, and is made of aluminum alloy. The research team has realized the integration and lightweight design of the receptacle with subversive technological innovation program, developed high density, high-precision laser selective melting and forming and precise control of post-processing methods, and successively conquered key core technologies such as integrated design technology of the structure and function of the receptacle, densification forming technology of thin-walled structure, and post-processing technology of aluminum alloy internal runner, and so on. Based on the realization of integrated molding, the development cycle of the storage box is shortened by 80% and the cost is reduced by 62%.

this isThe first 3D-printed aluminum alloy storage tank in China to be integrally molded and applied in orbitIn addition to the highly integrated installation of all components on the tank, the tank also realizes the connection between each component through the 3D printed runner, without the need for conduit connection. The development team has fully implemented the digital design concept of "multiple iterations in the digital world and one success in the physical world", adhered to the development mode of "ultimate product improvement", and reached the domestic first-class level in the development of 3D printed storage tanks, and has made great efforts to "catch up with and surpass the world". "We are striving to catch up with and surpass the world's advanced level, and contributing new strength to the aerospace industry.

Source: AMReference

On April 4, 3D Printing Technology Reference noted that a traditional metal injection molding developer called Greene Group Industries (GGI) acquired Holo, a developer of indirect metal 3D printing technology, in an event that is actually of significant landmark significance.One is that "advanced" 3D printing technology has failed to find enough industry applications to support its healthy growth, and the other is that traditional manufacturing industries have recognized the value of 3D printing technology to their production processes.The

Holo isAutodeska spin-off company of the company that developed the light-curing-based PureForm metal indirect 3D printing technology that enablesPure copper, stainless steel, titanium alloy, nickel-based high-temperature alloyRapid prototyping and scale-up production of complex metal parts in materials such as...In particular, it should be noted that the company was the first to tackle pure copper 3D printing based on DLP technology.Through DLP + DegreasingSintering processThe densities of the formed pure copper average 96-98%, which is sufficient to achieve the thermal and electrical conductivity of 95% for bulk copper. Additionally, the process may reduce the cracking problems associated with laser printing. Based on an already proven process, Holo is focusing on the development and manufacturing of heat sink parts rather than selling 3D printers.3D Printing Technology Reference 2021 reports that one of its pilot production lines20,000 pure copper small parts can be produced per monthand hopes to produce millions of copper heatsink parts each year.

With a 100-year history of providing high-quality metal parts, GGI is recognized as an industry leader in a variety of metal forming technologies, including stamping, forming, CNC machining, wire EDM, and metal injection molding (MIM). Its advanced manufacturing, sales, and support network allows it to quickly provide prototypes and develop short-run production processes from initial product concepts.

Holo's technology complements our metal injection molding, stamping and precision machining offerings," said GGI's CEO. This deal allows GGI to deliver prototype metal parts in less than two weeks with surface quality and feature resolution comparable to metal injection molding.PureForm additive manufacturing technology will strengthen our partnership with our customers by supporting faster iterations throughout the product lifecycle., while GGI maintains its superior engineering services and quality."

Holo's flagship PureForm additive manufacturing technology uses a metallic paste made from a blend of MIM powder and light-curing resins to enableDeveloping Indirect 3D Printing of High-Resolution, High-Throughput Parts. Specifically, the technology produces high-precision part blanks based on the principle of photopolymerization from a mixture of metal powder and photosensitive polymers. A mask exposure allows precise and fast molding of the entire layer, and the polymer binder selectively cross-links locally, bonding the metal powder together. The printed blank is degreased and sintered to form a densified part.

Indirect metal 3D printing.end upIntegration with the MIM industry

The back-end process of indirect 3D printing technology is identical to that of MIM technology, making it very easy for traditional metal injection molding manufacturers to incorporate the technology into their production process.

Indirect 3D printing technology helps enable rapid prototyping that is difficult to achieve with traditional manufacturing methodsThis is the type of technologyOne of the key values for the MIM industryGGI's acquisition of Holo is a key reason why 3D printing technology is an important complementary or even disruptive technology for early part development in the MIM field, as it eliminates the need for molds and dies and significantly improves development flexibility, shortens development time, and reduces development costs.

Currently, indirect metal 3D printing technologies such as binder jetting and light curing use powder for MIM as the 3D printing material, which has not increased the material cost for the MIM industry. For indirect metal 3D printing based on light curing, it is possible to achieveUltra-precision 3D printingBetter surface quality and finer detailed features.surpassing evenMIM-standardized parts. On top of that, Holo claims that its technology enablesScale production of complex designsand is considered ideal for aerospace, automotive, medical, electronics and industrial applications.

Source: AMReference

On April 12, the 130-ton reusable liquid-oxygen kerosene engine independently developed by the Sixth Academy of Aerospace Science and Technology Group successfully completed two start-up ground ignition tests. So far, the engine has completed a total of 15 repetitive tests, 30 ignition starts, the cumulative length of the test exceeded 3900 seconds, the number of repetitive tests exceeded the record number of tests of China's main engine of liquid rockets, laying the foundation for the subsequent first flight of China's reusable launch vehicles.

Power comes first in the development of spaceflight. The prerequisite for the development of reusable rockets is to take the lead in developing a successful reusable engine. It is reported that, compared with traditional disposable rockets, reusable rockets will add four key technologies: first, "accurate (landing)", and two."have a good connection", and three."last forever", and four."quick fix". And these key technology breakthroughs, the development of reusable engines bear the brunt. This type of engine as a follow-up to China's reusable launch vehicle main power, with high comprehensive performance, strong expansion capabilities, high reliability and other characteristics.

In terms of design and development, the Sixth Academy's development team adheres to the development concept of "technical limit mapping, extremely fast R&D iteration, and extreme product improvement", and practices the spirit of "must catch up with and exceed the world's advanced level", and has answered the question of how to "land accurately" and "connect steadily" by mastering a number of core key technologies such as multi-ignition, wide-range inlet pressure, start-up, and wide-range variable thrust. By mastering multiple ignition, wide range of inlet pressure, wide range of variable thrust and other core key technologies, the institute has answered the question of how to "land accurately" and "catch steadily"; by breaking through the technologies of fast and simple maintenance and condition inspection and evaluation, the institute has solved the problem of "not broken" and "repaired". Through the breakthrough of fast and simple maintenance and condition inspection and assessment technologies, the problem of "not broken" and "fast repair" has been solved; through in-depth analysis of the mechanism, continuous optimization of the structure, and full implementation of test validation, the weak links of the engine are comprehensively managed, and the inherent reliability of the engine has been continuously improved.

In terms of intelligent manufacturing, the development team of the Sixth Academy has planned and implemented 69 research projects for technological research and improvement based on a flexible and agile unitized manufacturing system and an efficient and integrated digital management and control system, and with the requirements of the key technical indicators of the reusable engine as the traction, the Sixth Academy is now planning and carrying out 69 research projects for technological research and improvement.Breakthrough in additive manufacturing one-piece molding of complex structural assembliesThe company has established a core technology system for the production and manufacturing of reusable engines, and has significantly improved the advanced and stable engine technology, product quality consistency and reliability.

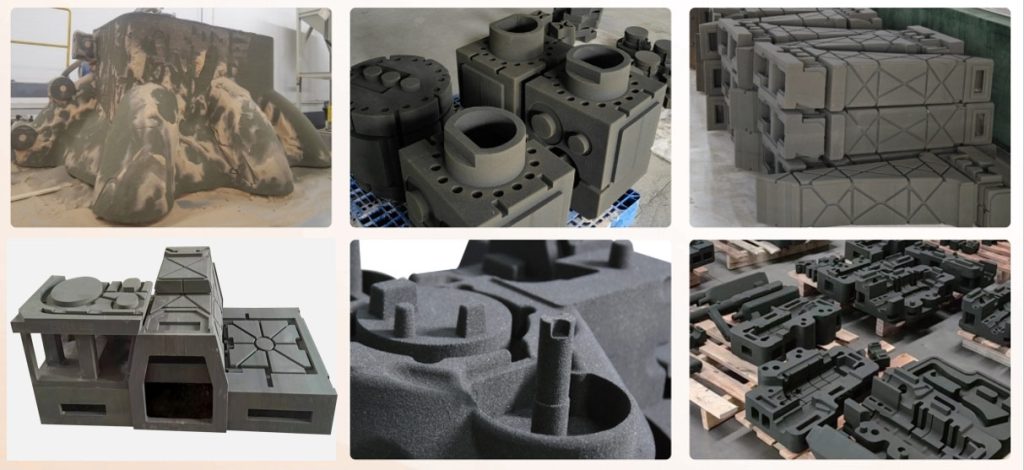

In recent years, with the development of manufacturing industry and technological progress, 3D casting technology is gradually showing its unique application value in various fields. Especially in the field of ultra-large castings manufacturing, the application of 3D casting technology by the domestic and foreign head manufacturers in related fields of concern and favor.

According to the information, Tesla, BMW, BYD and other car companies are already using 3DP sand mold printing technology. Tesla uses 3D sand casting technology to quickly and cost-effectively verify the design and engineering specifications of giant molds. A concept model of Mercedes-Benz uses 3D sand casting to realize the casting of single large-size parts of the rear subframe, suspension bracket and other structures. Domestic BYD new battery company is exploring 3D printing technology in the new energy vehicle prototyping, automotive parts and thermal management systems and other areas of forward-looking application development.

In the aerospace field, 3D sand casting technology can be used to manufacture engine parts, spacecraft structural parts, power units and other important parts. Can effectively solve the oversized, multi-dimensional curved surfaces, complex structure of the workpiece molding problems, in small quantities of large size mold manufacturing as well as special industry mold iterative upgrading research and development on the traditional manufacturing process can not be compared with the advantages. In the field of energy and power, 3D casting technology can be applied to large-size pressure-resistant complex cavity structure, large thin-walled lightweight parts and other manufacturing.

It can be seen that large casting manufacturing has a wide range of application needs in the fields of aerospace, shipping, pumps and valves, automotive (new energy), energy power (electrical), industrial machinery (robots/UAVs), rail transportation, 3C electronics, sculpture, education and research, rehabilitation and medical care, etc., and the traditional manufacturing methods are facing a lot of challenges, especially in the R&D trial stage of new products. For example, due to the huge size of castings, they usually need to be split into parts for casting and then integrated by welding, which not only increases the design burden, time and cost, but also easily leads to welding defects, affecting product quality and consistency. At the same time, modifying the mold is also a challenge.

The 3D casting technology can give a better solution for many characteristics of large castings:

1. Complex structure design optimization. 3D printing technology can manufacture complex shapes and structures that are difficult to achieve with traditional processes, further expanding the design space and providing more innovative possibilities.

2. Lightweight products. 3D printing technology can achieve local optimization of materials and hollow design, so that parts can maintain sufficient strength, but also to reduce weight.

3. Function integration integration. In the automotive industry, 3D printing technology has been heavily used in the integrated design, the same parts to achieve multiple parts, a variety of functions of the integration.

4. Batch customization. Batch customization of large castings using traditional processes to open the mold high cost, long cycle, 3D printing can save time and cost of opening the mold, improve efficiency and cost savings.

In order to meet the market demand for large-scale casting manufacturing, 3D printing equipment and rapid manufacturing service provider Beijing SANDY Technology Co., Ltd. was the first in China to launch a self-developed large size 3DP sand printer 3DTEK-J4000, the device breaks through the traditional processing size limitations, the maximum molding 4 meters of sand. Equipment creatively used without sand box flexible area molding technology, breaking the equipment molding size, the larger the price of the equipment wildly soaring strange phenomenon, making 4 meters or larger size of the equipment, and 2.5 meters of the price difference between the equipment to become possible. Economy, flexibility, with lower unit cost and shorter delivery time, cost-effective realization of oversized sand molding manufacturing, and can be customized according to user needs on-demand expansion of the printing platform to meet the production needs of the 10m + level (6m/8m/10m equipment has been in the synchronization of accepting bookings), to help users maximize productivity. (Foreign friends can click here to learn about our large 3D printer)

The equipment adopts international first-line high-precision, high-throughput nozzle, with high-performance molding process and intelligent algorithm technology, which can provide users with excellent molding accuracy, balanced and controllable casting performance and excellent reliability. Equipped with high-speed vibration type powder spreading system, automatic powder circulation system and self-developed equipment control software, etc., the sand mold has good dimensional accuracy, high strength, low outgassing and excellent surface quality; the equipment is easy to operate, stable and reliable, with printing warning prompts, and the "visual monitoring and intelligent system" can realize real-time monitoring and record traceability of the whole process; the open-source material process can provide users with excellent casting performance with balanced control and excellent reliability. Traceability of records; open-source material technology, can be adjusted according to the user's needs; supporting high-performance resin binder, curing agent, cleaning agent, to ensure the quality and stability of molding.

A user giant, large plane, thin-walled structural components, the use of traditional welding and casting process is difficult to meet the requirements, the use of three emperor technology 3D casting process, 45 days to deliver two finished products, finished product size of 1800mm × 2000mm, wall thickness of 5.5mm.

A customer's giant aluminum alloy casting weighing 1.25 tons, with a diameter of 900mm at the lower end, 1200mm at the upper end, and a height of 1850mm, had high costs and long lead times in traditional manufacturing methods, and was unable to achieve the required complex structure. The delivery was completed in only 15 days by using 3D casting process of SANDI Technology, which saved a lot of time and cost for the customer.

The lightweight, large-surface, thin-walled new energy commercial truck subframe delivered to the customer by SANDI Technology weighs about 27KG, with a wall thickness of 5.5mm, and is made of high-quality aluminum T6061. Traditional casting requires 1-2 months for mold manufacturing alone, and the cost is high. The 3D casting process of SANDI Technology will complete the delivery of finished products in 2 weeks.

[About SANDI TECHNOLOGY

(3D Printing Technology, Inc.) is a 3D printing equipment and rapid manufacturing service provider, national high-tech enterprises, specializing in new enterprises, the Ministry of Industry and Information Technology additive manufacturing typical application scenarios supplier. It is also the innovator of "SLS+SLM+3DP+BJ" 3D printing technology, and its business covers the research and development and production of 3D printing equipments, 3D printing raw materials, rapid manufacturing services for finished metal parts, and technical support services for 3D printing processes, etc. It has established a complete 3D printing rapid manufacturing industry chain, which is widely used in the following areas Aerospace, ships, pumps and valves, automotive (new energy), energy power (electrical), industrial machinery (robots / drones), rail transportation, 3C electronics, sculpture, education and scientific research, rehabilitation and medical care and other industries.

Introduction:Because the 3C consumer electronics field presents an explosive market demand for 3D printing, Apple, Samsung, Huawei, BYD's supplier Kangrui new materials, with revenue of 2.47 billion yuan in 2023, is going to get involved in 3D printing! At the end of last year, a Huawei supplier in Guangzhou enhanced its 3D printing capabilities by acquiring a metal 3D printer manufacturer.

Gu Wenyu, member of the Standing Committee of Jiangyin Municipal Committee, deputy secretary of the CPC Working Committee and deputy director of the Management Committee of Jiangyin High-Tech Zone, said at the signing ceremony that Jiangyin High-Tech Zone has been actively implementing the strategy of innovation drive in recent years, with a focus on supporting the development of high-end equipment industry, especially the 3D printing industry. For enterprises such as Kangrui and SanDi Technology, Hi-Tech Zone will provide all-round support to accelerate project construction and jointly promote the vigorous development of the industry.

Figure: Zhu Wei, Chairman of Jiangsu Kangrui New Material Science and Technology Co., Ltd. introduces the project development (left); Zong Guisheng, Chairman of Beijing SANDI Technology Co., Ltd. introduces the industrial cooperation (right)

SANDI Technology and Kangrui New Material are both active practitioners of new quality productivity.

Over the years, SANDI Technology has been actively promoting the development strategy of "3D Empowerment" and "3D3C" with the vision of "Starting from 3D printing, upgrading manufacturing with digital technology". Under the guidance of this strategy, SANDI has not only realized its own technological innovation and breakthrough, but also empowered many casting and injection molding enterprises, injecting new vitality into the production of 3C products.

With an annual production capacity of over 20,000 tons of precision metal materials, Kangrui New Materials focuses on providing high-precision, high-performance precision metal materials of specific materials and structures for downstream customers in the field of precision manufacturing. The company's products include metal laminated composites (titanium-aluminum composites, steel-aluminum composites, copper-aluminum composites), precision metal profiles, and precision metal polished rods, fine wires, and other multi-morphic precision metal materials, which are used in consumer electronics, automotive parts, industrial equipment parts, medical equipment and other applications.

With its advanced adhesive jet 3D printing technology, SANDY Technology has successfully realized the mass customized production of casting and injection molding, providing a brand new solution for the manufacturing of complex parts, empowering the development of casting and injection molding enterprises, and providing rapid manufacturing services through more than ten subsidiaries distributed in China. At the same time, SANDI Technology utilizes its nearly one hundred patented laser 3D printing technologies to enter the application field of 3D printing in 3C products, obtains the first domestic registration certificate of 3D printing customized titanium alloy hearing aids for medical devices, and quickly cuts into the field of manufacturing through the cooperation of communication terminal parts.

The relevant person in charge said that this cooperation with Kangrui new materials, first of all, to develop and produce 3C special 3D printing equipment, to realize 3D printing intelligent, automated, low-cost mass production of communication terminal parts; and then promoted to other applications, such as new energy vehicles and so on.

Polar Bear 3D Printing

If Apple, Huawei, Samsung, Xiaomi, Glory, OPPO, vivo, these 3C big manufacturers really adopt 3D printing process in large quantities, it is difficult for domestic manufacturers to be able to withstand so many production tasks at present. It may take hundreds or even thousands of metal 3D printers, printing titanium alloy powder up to a thousand tons/year, to meet the delivery of high-volume parts.

Relevant institutions predict that within 2030, the largest application market of 3D printing technology will appear in 3C consumer electronics/automotive and other civilian areas, up to the level of hundreds of billions of dollars, more than the current military defense market, presenting several billions or even tens of billions of dollars of level of the application of the enterprise.

With the iterative upgrading of 3D printing technology and the decline in the cost of raw materials, 3D printing continues to improve efficiency and reduce costs, and the downstream application areas continue to expand. Especially with the domestic and foreign consumer electronics head manufacturers have layout 3D printing technology in smart phones, watches and other 3C products, such as folding screen cell phone shaft cover, electronic watch case, cell phone frame, bezel and other parts using 3D printing technology manufacturing, 3D printing technology in the 3C consumer electronics parts in the mass production of the application (3D3C) is accelerating penetration. According to Statista and Wohlers data statistics, in 2022 the global consumer electronics market size of about 1.01 trillion U.S. dollars (about 7.27 trillion yuan), of which the market size of 3D printing in this field is 2.127 billion U.S. dollars (about 15.306 billion yuan), the penetration rate is only about 0.21%, with great upside. CITIC Securities "Electrical Wisdom Industry 3D Printing Research: Titanium Alloy and 3D Printing from Consumer Electronics" report shows that only titanium alloy 3D printing in the field of consumer electronics market space is expected to exceed 10 billion yuan, 3D printing in the field of consumer electronics has a huge space for development of hundreds of billions of dollars.

In the 12th Shanghai Injection Molding Forum held on March 6, Dr. Zong Guisheng, Chairman of Beijing SANDI Technology Co., Ltd, in a report entitled "SANDI 3D Printing of Metals and Ceramics in the 3C Industry", reviewed the technical research and application progress of 3D printing in the field of 3C electronics, analyzed the problems and bottlenecks faced by 3D printing in the application of 3C, and explored the technology of 3C applications. development direction.

The manufacturing of 3C products requires high surface quality, part flatness, dimensional accuracy, high product demand, automated production and low cost. Based on the above characteristics, at this stage, SLM selective laser melting and BJ binder jetting can be used for the manufacturing of 3C electronic parts and components through two main technology processes. Among them, the SLM process is characterized by high precision, high complexity and high densification, while the BJ process has excellent surface quality and dimensional accuracy, high efficiency and high throughput.

The use of 3D printing technology in smartphones and watches can achieve high strength and lightweight products, while optimizing production time and reducing production costs. For example, a manufacturer using titanium alloy 3D printing of folding screen cell phone hinge shaft cover, the thickness of only 9.9mm, the strength of the enhancement of 50%, while reducing the weight of 62%, the number of hinged parts from 92 reduced to only 4; titanium alloy 3D printed cell phone center frame, weight reduction of 9%.

Why use titanium alloy material? Dr. Zong Guisheng from the titanium alloy of several major characteristics of the analysis: titanium alloy of high specific strength, aluminum alloy 1.3 times, magnesium alloy 1.6 times, stainless steel 3.5 times; titanium alloy of high thermal strength, can be in the 450-500 ° C temperature long-term work; titanium alloy of corrosion resistance is good, acid, alkali, and atmospheric corrosion, pitting corrosion, stress corrosion resistance is particularly strong; titanium alloy of low-temperature Titanium alloy low temperature performance is good, the gap element is very low titanium alloy TA7 in -253 ° C can also maintain a certain degree of plasticity; titanium alloy chemical activity, high temperature can be with hydrogen, oxygen and other gaseous impurities in the chemical reaction, the generation of hardened layer.

Why use 3D printing technology? Dr. Zong Guisheng said, for one thing, the traditional machining of titanium alloy has certain bottlenecks. Because of the high temperature titanium chips easy to burn, poor thermal conductivity, chemical affinity, small modulus of elasticity, cold hardening phenomenon is serious and other problems, resulting in tool wear, workpiece clamping deformation, parts fatigue strength reduction and other problems. Secondly, there are certain problems in the manufacture of titanium/aluminum composite panels. The traditional solid? Solid composite preparation method is susceptible to time, temperature and diffusion coefficient and other factors, resulting in interface metal bonding quality, low material utilization and other issues. Third, 3D printing can realize high integration and reduce assembly. Take the water drop hinge of the folding screen cell phone as an example, the number of parts is as many as 130+, and each part needs to be accurately aligned, which makes it extremely difficult to design. Module assembly technology is complex and involves many patent barriers, so the yield of finished products is low after multiple processes. Fourth, 3D printing to help reduce the cost of titanium alloy manufacturing, releasing a larger market space for 3D printing, and promoting its large-scale application.

As a 3D printing total solution provider focusing on green rapid manufacturing, based on years of laser 3D printing 1.0 equipments and applications, SANDI Technology has independently mastered 3DP, BJ binder jet 3D printing 2.0 equipments, materials and processes, which can meet the manufacturing needs of products of different sizes (from millimeter to meter) and provide users with full-size, multi-material and full-chain rapid manufacturing services. At present, SANDI Technology is exploring the application of 3D printing in 3C electronic field through independent research and development of technology process and industrialization cooperation with supply chain enterprises of famous 3C manufacturers.

For example, the titanium-aluminum alloy laminated composite cell phone frame printed with SANDY SLM can improve the interface strength by 40% compared with the traditional rolling process. customized in-ear hearing aids printed with SANDY SLM have titanium alloy shells up to the ultimate wall thickness of 0.15mm, are lightweight, invisible, 15 times tougher to resist falls, safe and non-allergenic. The product has obtained the national registration certificate for Class II medical devices and realized mass production.

SANDI Technology has completed the development of BJ binder jet metal/ceramic molding equipment such as R&D type R series and production type P series, and dozens of equipments have been installed and used; completed the development of systematic material processes for iron-based materials, non-ferrous metals, high-temperature alloys, refractory metals, ceramic materials, inorganic salts, polymer materials, food materials, etc.; and responded to the multi-species by advancing the CAE simulation and prediction solutions, small batch agile manufacturing needs. In addition, three emperor technology joint Shenzhen Vocational and Technical University to build a joint laboratory of additive manufacturing technology, at the same time, joint Shenzhen Tsinghua University Research Institute, Shanghai Jiaotong University and other research institutes of the relevant team to jointly carry out binder injection molding and other materials, process and application of basic technology research, and to promote the industrialization of the industrial molds, cutting tools, 3C electronic products, and complex, large size and complex ceramic products and other fields of application. Application.

For the application of 3D printing in 3C field, Dr. Zong Guisheng said that the market potential of this application is very large, and the current SLM and BJ technologies have relevant application prospects, but there is still a need to solve a series of problems such as product dimensional accuracy, surface finish and automated mass production. Regarding the direction of technology development for 3C applications, he proposed that automated production can be realized through the development of 3C-specific SLM equipment; in the future, Area Laser 3D Printing (AL3DP) technology, which has great potential for large-scale manufacturing, may become a new quality of productivity for the realization of applications such as 3C and bulky products, which is worth paying attention to and looking forward to.

March 6-8 at the Shanghai World Expo Exhibition and Convention Center is being carried out 2024 16th China International Powder Metallurgy, Cemented Carbide and Advanced Ceramics Exhibition, welcome to visit SANDY booth (Hall H1 A913) to visit and exchange ideas!

Ltd. jointly with Shanghai Jiao Tong University and Liaocheng Institute of Vocational Technology, and jointly with relevant industry enterprises, vocational schools and ordinary schools of higher education, scientific research institutions, relevant industry organizations, consultants and investment institutions, industrial parks and other more than a hundred members of the National Additive Manufacturing Industry Industry Industry-Education Integration Community (hereinafter referred to as the " (hereinafter referred to as "Community") was founded and the first session of the Council was held in Liaocheng, Shandong Province.

Deng Junqing, second-level inspector of Shandong Provincial Department of Education, Wang Guangkui, first-level researcher of Liaocheng Municipal Government Office, Wang Zhiqiang, assistant director of Mechanical Industry Education and Development Center, Zong Guisheng, chairman of Beijing SANDI Technology Co. Economic and Technological Development Zone, Shang Tongshun, member of the party working committee and second-level commissioner of the management committee, and Zhang Lijuan, executive director of the Additive Manufacturing Research Institute of Shandong University of Science and Technology, gathered with representatives from various fields of government, enterprise, line and school to explore the integration of industry and education and build a new model for talent training in the additive manufacturing industry. The meeting was hosted by Xu Longhai, Deputy Secretary of the Party Committee and President of Liaocheng Vocational and Technical College, and Wang Lei, Director of the Education Division of Beijing SANDI Technology Co.

Zhang Xiaogang, president of the Chinese Society for Metals and former president of the International Organization for Standardization, sent a congratulatory letter to the conference and said that the establishment of the Community will play an important role in promoting the deep integration of the innovation chain, industrial chain and talent chain in the additive manufacturing industry. It is hoped that the Community can truly realize the fusion of science and education and the integration of industry and education, and make contributions to China's additive manufacturing industry.

Deng Junqing said in his speech that the establishment of the National Additive Manufacturing Industry Industry and Education Integration Community is not only a pragmatic move to promote the vocational and popularization integration, industry-education fusion, science and education fusion, but also an innovative strategy to convert the advantages of science and education resources into a winning trend in the development of the manufacturing industry. We hope that the community will effectively play the role of a platform to accelerate the deep integration of the industrial chain, innovation chain, education chain and talent chain, and create an industry-enabling "complex" and talent training "consortium" that can be integrated, landed, effective and influential.

Wang Guangkui said in his speech that the establishment of the National Additive Manufacturing Industry Production and Education Integration Community is a major innovative initiative taken in the field of equipment manufacturing. I believe that, under the impetus of the community, Liaocheng will usher in new development opportunities in various fields such as construction machinery, industrial robots, and major intelligent manufacturing equipment sets. It is also hoped that the relevant industry organizations, schools, research institutions, upstream and downstream enterprises work together to create a good industry and education in-depth integration, efficient service docking, support for the development of the industry across the regional additive manufacturing industry industry industry-teaching integration community.

Wang Zhiqiang pointed out in his speech, around the additive manufacturing industry talent cultivation, bring together the government, industry, enterprises and schools of quality resources, to build a new platform for additive manufacturing industry and education fusion community, not only to carry out the state to accelerate the construction of modern vocational education system to promote the reform of the key tasks of the specific requirements, but also to the development of the industry as a demand, and discuss how to cultivate, reserve talents needed for the development of the industry, to establish an industry chain-oriented, talent chain as the core, innovation chain as the driving force, education chain as the support, value chain as the link "five chain integration" linkage mechanism, strengthen the landing empowerment, focus on the high-end industry, promote talent It is also a specific initiative to discuss how to cultivate talents needed for industrial development, establish a "five-chain integration" mechanism with the industry chain as the guide, talent chain as the core, innovation chain as the driving force, education chain as the support, and value chain as the link, strengthen the landing and empowerment, focus on the high-end of the industry, and promote the innovative development of talent co-cultivation, mutual hiring of teachers, industry-university-industry-education linkage, and technological innovation and upgrading.

The General Assembly jointly considered and adopted the Community's constitution and the list of organizational members, elected Beijing SANDI Technology Co. At the same time, 25 vice-chairman units such as Shanghai Jiaotong University and Liaocheng Institute of Vocational Technology, 91 director units and 23 vice-chairman members were established.

Wang Lei on behalf of the Secretariat in the meeting released the community work plan, the community will focus on teaching resources teaching equipment joint development, joint training of skilled personnel, pre-service, job training and continuing education, technological innovation and construction, the results of the transformation of the entity to establish a mechanism to guarantee the construction of public services, information technology platform construction and other key tasks to carry out the work of the community has been in the list of dozens of implementation of the project can be carried out in collaboration with the joint members of the unit.

Dr. Zong Guisheng, Chairman of the Board of Directors, made a comprehensive and in-depth explanation on the construction of the Community from the aspects of positioning, ecology, main direction, basic structure, construction principles, etc. He said that, as the lead initiator of the Community and the Chairman of the Board of Directors, SNDT, relying on its own strengths in the fields of technological research and industrial application, will integrate resources, open up the environment, strengthen the synergy, and do a good job in the service, and is committed to build the Community as the world's leading additive manufacturing industry development ecosystem system. We are committed to building the Community into a world-leading additive manufacturing industry development ecosystem system, accelerating China's additive manufacturing industry international leadership, industrialization and industrialization of applications, and ultimately creating an enabling industrial Internet platform that "serves the region, focuses on the industry, empowers enterprises, cultivates talents, and operates the ecosystem".

In the meeting, Liaocheng Economic and Technological Development Zone party committee members, management committee of the second level commissioner Shang Tongshun, Shandong University of Science and Technology Institute of Additive Manufacturing Executive Director Zhang Lijuan, Shanghai Jiao Tong University School of Materials Science and Engineering researcher Dr. Li Fei, Changzhou Institute of Mechanical and Electrical Vocational and Technical College, President Xu Zhaoshan and other leaders, experts and other leaders, speeches or speeches.

[About SANDI TECHNOLOGY

Beijing SANDI Technology Co., Ltd. is a high-tech enterprise focusing on 3D printing green rapid manufacturing equipment and services, the business covers the development and production of 3D printing equipment, rapid manufacturing services for finished metal parts, the research and development and production of 3D printing raw materials, and has established a more complete 3D printing rapid manufacturing industry chain, which is widely used in the aerospace and military industry, automotive, rail transportation, ship pumps and valves, Engineering machinery, education and scientific research, sculpture and cultural creation, rehabilitation and medical care and other industries.