After nearly 40 years of development, 3D printing technology has become a powerful tool for advanced manufacturing nowadays, with great development potential. According to Wholers data statistics, the global 3D printing market reached $15.244 billion in 2021, with a compound annual growth rate of 20.4%. According to the China Additive Manufacturing Industry Alliance data statistics, China's 3D printing enterprise revenue reached 26.5 billion yuan in 2021, with an average annual growth rate of 30%, which is higher than the global average growth rate, showing the world's first manufacturing The big country's attention to new manufacturing technologies and achievements.

It can be seen that the market growth rate of 3D printing is quite high, the whole industry scale is growing year by year, but compared with other industries, 3D printing is still a small industry. The reason for this is that the main constraints on the printing efficiency of 3D printing and material costs. For example, based on "point scanning" laser powder bed molten metal 3D printing technology, its aerospace, automotive, military, molds, medical and other fields of small quantities of precision metal parts manufacturing has many applications, but also compared to traditional manufacturing technology has more advantages, but for most industrial users, 3D printing to get a larger scale industrialized Application, there is an urgent need to solve the "slow and expensive" problem.

Binder Jetting (Binder Jetting/3DP, hereinafter referred to as BJ) is a high-efficiency, low-cost "line scanning" 3D printing technology, as early as 1993 was born in the United States at the Massachusetts Institute of Technology, due to the higher threshold of the process, the industry chain is much longer, the development process of the BJ technology lags behind the "dot scan" laser 3D printing technology. "Point scanning" laser 3D printing technology, but by virtue of efficiency and cost advantages, BJ technology is full of energy. In recent years, with a series of technological breakthroughs in the field of BJ, especially the successful development of BJ metal, once again by the industry's widespread attention, known as "Additive 2.0" technology. According to a SmarTech report, by 2030, indirect metal printing technologies such as binder jet 3D printing will realize an output value of 54 billion U.S. dollars (about 350 billion yuan).

Internationally, Desktop Metal, HP, Digital Metal and other companies in the past five years have completed the technical development of BJ metal technology, to achieve a certain degree of industrialization and application. Domestic BJ technology started later, but as a manufacturing country, China's market demand for BJ technology is more urgent, especially from the MIM (Metal Injection Molding) industry for rapid prototyping and small and medium-sized mass production needs. In this context, the rapid development of domestic BJ technology. It is understood that there are several domestic enterprises to BJ as a research project, of which, Beijing Longyuan Automatic Molding System Co., Ltd. (SANDI's subsidiary companies, hereinafter referred to as "Longyuan molding") has been put on the market equipment.

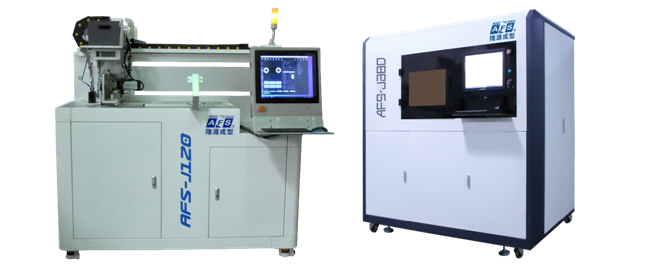

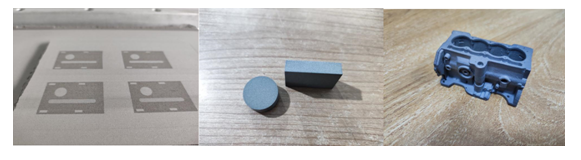

Longyuan Molding Company, a leading 3D printing technology company in China, completed the development of BJ metal technology and launched AFS-J120 and AFS-J380 equipment during 2018-2020. The equipments are built with integrated small particle size (5~15μm) low-fluidity powder precise feeding system, new powder spreading roller pressure system and high-precision inkjet printing system (1200dpi), which can realize ±0.1mm printing precision, >3600cc/h printing speed and >55% green blank density, and the relevant technical indexes have reached the international advanced level.

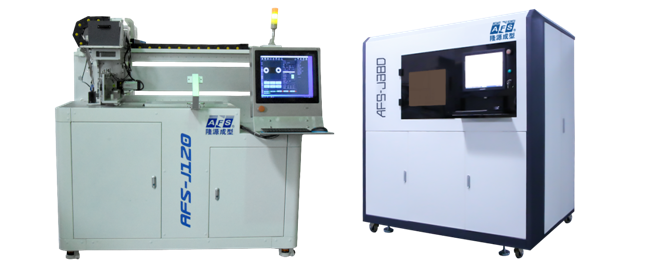

On the basis of the equipment, Longyuan Forming has successfully developed a series of BJ-specific binder formulations, which are suitable for more than 20 kinds of matrix materials, such as iron-based alloys, light metal alloys, organic glass, ceramics and so on. The team has conducted systematic research and analysis on the physical and chemical properties of the binder and the interaction between the binder and the powder, among which the water-based binder has the characteristics of green environmental protection, sintering low carbon and oxygen residue, etc., which has a good application effect. The degreasing and sintering process is a necessary back-end process to complete the manufacturing of BJ metals. The degreasing and sintering properties of the relevant BJ metal materials of Longyuan Forming have reached the international material standards of the MIM industry, and have the conditions for industrialization and application.

Binder jet metal 3D printing technology is considered to be one of the best ways to realize mass production of metal 3D printing due to its high printing efficiency, low material cost, cost-effective equipment, no additional support, and suitability for batch production, etc. The layout of Longyuan Forming in this field is also the implementation of its development concept of "platform + ecology" based on the core technology of 3D printing. The layout of Longyuan molding in this field is also based on the core technology of 3D printing, to create a "platform + ecological" development concept of practice.

"There are too many orders to do over, just finalized an order with a northeastern customer in the morning, the subject amount is more than 3 million yuan." February 18, spring snow covered the earth, Wugong County Xin Xin Nonferrous Metal Casting Co., Ltd (hereinafter referred to as Xin Xin casting) production workshop a busy scene, this small and medium-sized enterprise has the first introduction of 3DP sand printing rapid casting advanced technology foundry in Shaanxi Province, since the beginning of the spring, the production orders continue to come.

"With the technical support of the domestic 3D printing benchmark enterprise, now we can produce all kinds of complex structure molds, the efficiency has been increased by two times, and the cost has been reduced by half. At the same time, using the sales channels of the upstream enterprises, our casting products are also sold all over the country." Xinxin casting head Tan Dawei said, Gree Electric Appliances, Chery Automobile and other enterprises are their customers.

Just before the first half of last year, the non-ferrous metal casting enterprises are still urgently seeking "breakthrough" way. "The traditional casting process of high energy consumption, high pollution, product precision can not keep up with the requirements of the advanced manufacturing industry, in the country vigorously advocate the development of green casting industry in the context of the traditional casting enterprise development and transformation of the pressure is great." Tan Dawei said, in Wugong County, like them there are five enterprises, are facing similar development difficulties.

Casting industry is the backbone of modern manufacturing, a car has more than 15% parts produced by casting. To high-end, green, intelligent close, is the traditional casting enterprises to achieve high-quality development of the inevitable choice.

From the traditional casting development difficulties, to intelligent transformation of products into market recognition of the "meat and potatoes", Xin Xin casting is how to ride on the 3D printing green casting of the express, so as to enter the transformation and upgrading of the traditional casting enterprises in the fast lane?

It started with an "encounter" between Xianyang Municipal Bureau of Science and Technology and CICC.

"When we docked with CICC Capital for the transformation fund of scientific and technological achievements, we learned that Beijing SANDI Technology Co., Ltd (hereinafter referred to as SANDI Technology), which is led by CICC Capital, had the idea of merging and acquiring casting enterprises, and then we shared this information with the casting enterprises in Xianyang City, and the relevant enterprises were very interested in it." Shen Yan, a staff member of the Science and Technology Bureau of Xianyang City, said that they provided a list of casting enterprises in Xianyang City to SANDI Technology, which paved the way for in-depth cooperation afterward.

At the same time, Wugong County, then in charge of industry and investment promotion work of the deputy governor Liu Wei in the three emperor science and technology chairman Zong Guisheng on the cooperation matters in-depth discussions, after the Wugong County Governor Yao Junfeng also led the relevant departments to Shenzhen to visit the three emperor science and technology companies, and further strengthened the confidence of the two sides of the cooperation.

In this way, a Beijing science and technology, capital and the traditional casting enterprises in Xianyang bridge up. At that time, three emperor science and technology in other parts of the country to investigate the object of cooperation, and Xin Xin casting can seize this opportunity to obtain favor, the key to its success lies in the "efficiency".

"Beijing's enterprises are very efficient, and after indicating our intention to cooperate, we quickly contacted SanDi Technology, and we finalized our partnership in two months' time." Tan Dawei said that with the cooperation bridge built by the Science and Technology Bureau of Xianyang City, their two enterprises with strong complementarity in business quickly found an entry point for cooperation.

"We are interested in Xinxin Casting's more than thirty years of industry accumulation, good business conditions, mature technology processes and the ability to provide efficient, continuous and high-quality services to users. All of these qualities fit well with the strategic layout of SANDI Technology's commitment to building a new ecology for the 3D printing green casting industry." Li Changqing, Deputy General Manager of SANDI Technology, said.

In addition, according to Li Changqing, Xi'an and Xianyang have more scientific research institutes and R&D enterprises, and such customers have a greater market demand for rapid trial production and project validation, and their cooperation with Xinxin Casting located in Wugong County of Xianyang City can further extend their market reach in Xi'an and neighboring cities; on the other hand, the business environment in Shaanxi is getting better and better, and the Science and Technology Bureau of Xianyang Municipality has provided them with On the other hand, the business environment in Shaanxi is getting better and better, and the Science and Technology Bureau of Xianyang City has provided them with great support to look for cooperation opportunities.

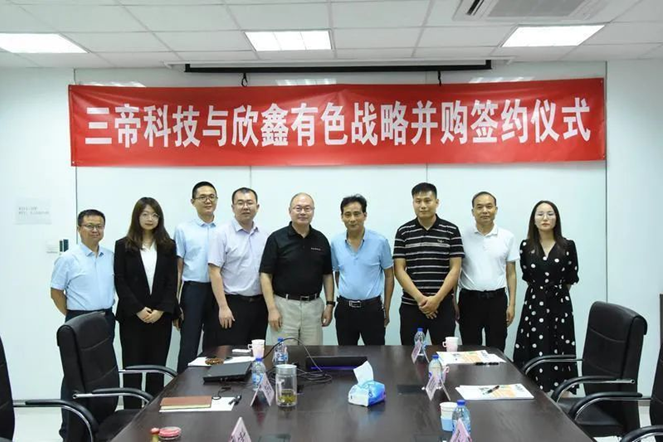

After 2 months of negotiation, the two sides 5 times consultation, this CICC capital and the Science and Technology Bureau of Xianyang City, "matchmaking", to realize the innovation elements of cross-regional integration of the cooperation was finalized. Xinxin casting became a subsidiary of three emperor technology holding, three emperor technology in Xinxin casting into the province's first 3DP inkjet sand printing equipment.

"The equipment can realize moldless molding, replacing the traditional casting production line in the mold manufacturing and casting manufacturing links, eliminating the cost and time of opening the mold, eliminating the unreasonable design of the mold and the risk caused by the repair of the mold, high-precision integrated molding, which can be eliminated by splitting the mold, the quality risk caused by the group mold." Xin Xin casting Tan Dawei introduction, the technology can significantly shorten the cycle of product development and trial production, saving development costs, accelerate the time to market, applicable to aerospace, automotive, motorcycle, rail transportation, ship pumps and valves and other fields.

"'3D printing + casting' gives us wings, not only further strengthens Xinxin Casting's advantages in high-end complex castings, but also greatly expands Xinxin Casting's business scope and market share, making mass production of high-end castings possible." Tan Dawei said, at present, Xinxin Casting's new plant is under construction, after the completion of the plan to invest in another 8 to 10 sets of 3D printing equipment to further meet market demand.

According to Ma Zhengwei, Executive General Manager of CICC Capital, the in-depth cooperation between SANDI Technology and Xinxin Casting is a positive attempt for small and medium-sized foundry enterprises in the transition period to implement intelligent transformation based on 3D printing technology and establish green, flexible and high-end casting capabilities.

"At present, in the context of fully promoting the construction of the core area of the Qinchuangyuan Innovation Driving Platform Xianyang, Xianyang City empowers traditional industries through science and technology, realizes the 'government, industry, academia, research and financial services' resonance at the same frequency by means of three-dimensional linkage, and links enterprises, universities, institutes, and financial service institutions with the market as an intangible hand, to Helping Xianyang city's economic transformation and upgrading to achieve high-quality development." Yang Chongfeng, director of the Science and Technology Bureau of Xianyang City, said. (Source: Shaanxi Daily) (Author: Liu Kun)

(hereinafter referred to as "SANDY") held its annual meeting on February 3rd. Dr. Zong Guisheng, Chairman of the Board of Directors of SUNIX, Liang Hong, Chairman of Beijing Longyuan Forming, Dr. Pu Xiongying, Deputy General Manager, and Xia Benhua, Deputy General Manager of SUNIX's Healthcare Segment, attended the meeting.

In his New Year's speech, Dr. Zong Guisheng reviewed the achievements and shortcomings of SANDI Technology in the past year and released the development strategy for 2018. He proposed that in 2018, SANDI Technology should continue to focus on and open up the two business segments of additive manufacturing and rehabilitation medical care, realize the company's brand value through the improvement of products, channels and services, and build a service-oriented manufacturing enterprise. At the same time, Dr. Zong Guisheng also put forward his expectations for the team, namely: ownership mentality, professionalism, and purity of people.

In the annual commendation meeting, excellent employees Liu Xianzhu, by Junfeng, Wang Hongyan; sales champion Zhang Changtao; excellent newcomer Liu Guanghua; 5-10 years old employees Liu Rui, Zhang Yongjun, Zhang Guoqin, Li Zuofeng, Wang Juan, Li Yongliang; 10-20 years old employees Dou Changwei, Zhao Long, Jin Xiaoming, Wang Jingfei, Zhu Hualin, Gao Peng, Li Jianhua, Li Guofeng; more than 20 years of veteran employees Li Huaxin, a total of 20 people were Recognition.

Please give a round of applause to the above outstanding SANTI TECHNOLOGY people!

SANDI technology people are like this, obviously can rely on professional ability to eat, but still want to show their own talent ...... Here officially open our Happy hour!

Can't get enough of just looking at pictures?

It's okay, my thoughtful editor has already prepared a video feast for you! Let's go and have a good time!

A collection of catchy songs strung together! Do not hesitate to open the video!

https://v.qq.com/iframe/player.html?vid=n0547frn8ih&tiny=0&auto=0

A heartwarming, inspirational skit that wishes all those who work hard to get ahead in the end!

https://v.qq.com/iframe/player.html?vid=r0547zzgshv&tiny=0&auto=0

It is said that an annual meeting is not perfect if there are only wonderful performances, so let the rounds of exciting lucky draws be the strong cardiovascular agent interspersed between the programs! Let the screams and cheers come harder!

A new year, a new journey; new blessings, new expectations.

SANDY TECHNOLOGY wishes everyone in the new year: Golden Dog Jade Dog, Woof to Fortune! Good luck, health and peace!

September 2, hosted by the Liaoning 3D Printing Industry Association, Liaoning Juzi Industrial Co. "The inaugural meeting of the Association was held in Shenyang International Convention and Exhibition Center. Leaders from Liaoning province and city, as well as experts, scholars and entrepreneurs in 3D printing industry were invited to attend.

In the morning of the Association's founding meeting, the election of the first leadership list, Liaoning Juzi Industrial Co., Ltd. Lu Shengping, Chairman of the Association, the former Deputy Director of the Shenyang municipal people's Congress, Song Tieyu, Chairman of the Board of Directors of the Beijing SANDY Printing Technology Company Limited, Dr. Zong Guisheng Honorary President of the Association.

In the future development, the association will coordinate the 3D printing technology and industry-related resources within the scope of Liaoning Province, enhance the level of research, development, manufacturing and service in the field of 3D printing technology-related areas, promote the promotion and application of 3D printing technology standards, protect intellectual property rights and promote industrial development. Unite and lead the members, vigorously carry out cooperation among industries, universities and research institutes, make joint breakthroughs in technological innovation of emerging science and technology industry, form a technological innovation cooperation organization for emerging science and technology industry with joint development, complementary advantages, benefit sharing and risk sharing, drive the technological progress of the industry, and enhance the overall competitiveness of the industry. To make the emerging technology industry bigger and better, and to realize the rise of Liaoning Province's comprehensive strength at a high level.

In the afternoon, the "3D Printing and Enterprise Transformation and Upgrading" Summit Forum was hosted by Dr. Zong Guisheng, Chairman and CEO of Beijing SANDI Printing Technology Co.

Zong Guisheng: 3D Printing and Enterprise Transformation and Upgrading

Dr. Zong Guisheng firstly analyzed the current situation of China's manufacturing industry. Although China became the world's largest manufacturing country in 2010, there are still many problems such as low level of overcapacity, low management level, low technological content and value-added products, and weak technological innovation ability. Facing the loss of cost advantage, forced mandatory elimination, the Internet impact fierce, the industrial environment has changed dramatically the heavy challenges. The transformation and upgrading of Chinese manufacturing enterprises is imminent.

How to transform? Dr. Zong Guisheng believes that we should start from the integration of "intellectual manufacturing" and the social value chain, the integration of "quality manufacturing" and the civilized development of the ecological chain, the integration of industrial chain extension and industrial integration, the integration of new high-tech industries and traditional industries, etc., and ultimately achieve the transformation to "Light", "refined", "strong" transformation.

In recent years, from the U.S. Obama administration will be listed as 3D printing to stimulate the return of the manufacturing industry, accelerate the U.S. economic growth of an important "weapon", to Germany's "Industry 4.0" strategy to support the development of a new generation of revolutionary technologies in the field of industrial R & D and innovation, and then the domestic "Made in China 2025" plan clearly to enhance the overall competitiveness of China's manufacturing sector tasks and goals. Made in China 2025" plan clearly enhances the overall competitiveness of China's manufacturing industry tasks and goals, the global manufacturing countries have introduced competitive strategies. Today, with the escalating challenges of global manufacturing, in order to be undefeated in the competition, we need to improve efficiency, shorten the time to market, and enhance flexibility, and these needs have driven the development of smart manufacturing. 3D printing, as one of the core technologies of smart manufacturing, has the great potential to change the entire production industry, and is expected to become the key link in China's high-end manufacturing industry, and to promote the upgrading of China's manufacturing industry.

3D printing creates a new ability to produce items of all shapes and sizes, enabling engineers to design more complex products that were previously unattainable.3D printing is widely used in aerospace, automotive manufacturing, foundry, medical, digital construction, civil, and other fields of rapid prototyping and additive manufacturing due to its advantages of manufacturing complex parts, product diversification at no additional cost, no assembly, cloud-based manufacturing, zero-skill manufacturing, portable manufacturing, and net molding. and other fields of rapid prototyping, rapid manufacturing. However, if you do not change the rules, requirements and expectations, 3D printing compared to traditional manufacturing has many defects, can not be used to replace the traditional mature manufacturing methods; and if you change the rules, requirements and goals, 3D printing as another manufacturing method, incremental development, 3D printing will bring a new era of design, manufacturing. Looking to the future, we should apply 3D printing thinking to design and manufacture products, embrace intelligent manufacturing, use 3D printing thinking to design and manufacture products, and promote enterprise transformation.

Li Shujun: "Electron beam molten metal molding technology in orthopedic implantable device applications".

Dr. Shujun Li from Shenyang National (Joint) Laboratory of Materials Science, Institute of Metals, Chinese Academy of Sciences, elaborated and analyzed the Electron Beam Melting Metal Forming (EBM) technology and its application in the field of orthopedic implantable devices. According to the introduction, EBM is a computer program-controlled high-precision rapid manufacturing technology, which can realize the design and manufacture of any structure of metal materials, the comprehensive mechanical properties of its materials are better than the casting process, and the metal powder can be recovered and recycled.

In recent years, the application of EBM orthopedic implantable devices has continued to grow. The main applications are: rapid manufacturing of individualized customized joints. Such as personalized customized knee joints, bone trabecular structure cranial repair implants, individualized customized hip joints, etc.; titanium alloy porous implantable devices. Such as gradient porous femoral head support rod, bone trabecular structure acetabular cup, porous cage implant material, etc..

Afterwards, Dr. Li Shujun gave a comprehensive analysis of the preparation process of EBM, mechanical properties of components prepared by EBM, and biocompatibility of components prepared by EBM, etc. He also pointed out that EBM is an advanced metal forming technology developed internationally in recent years. It is also pointed out that electron beam melting metal forming (EBM) is an advanced metal forming technology newly developed internationally in recent years. This technology can efficiently prepare high-performance titanium alloy individualized orthopedic implant devices and porous titanium alloy orthopedic implant devices, which can significantly improve the osseointegration ability of metal implants, and has a broad application prospect in the field of orthopedic implant device applications.

Wang Lianfeng: "Application of Laser Selective Melting in Aerospace

Prof. Wang Lianfeng, Director of Shanghai Aerospace Additive Research Laboratory, Distinguished Professor of University of Science and Technology of China (USTC), Vice Chairman of China 3D Printing Technology Industry Alliance and President of Shanghai Additive Manufacturing Association, introduced the laser selective zone melting additive manufacturing technology (SLM) and its application in aerospace. Laser selective melting additive manufacturing technology (SLM) is a technology in which metal powder is selected layer by layer under the thermal action of a laser beam to be completely melted, cooled and solidified and shaped, and its advantages in manufacturing efficiency, manufacturing precision, structural complexity, mechanical properties, etc., have made it the most urgently demanded additive manufacturing technology in the aerospace field. Many countries around the world have widely carried out related research and testing: for example, NASA uses SLM to print rocket nozzles and nozzle ignition tests; Monash University in Australia uses SLM technology to manufacture aero-engines, etc.; GE adopts SLM technology to develop key components of the combustion system of the LEAP engine; Honeywell uses it for the vertical take-off and landing drones to survey the Fukushima nuclear power plant after the leakage; China's related research has been carried out in the past few years. China's relevant research institutions are also targeting the weightlessness, vacuum, large temperature difference, limited power supply and other unique problems in space research, and has been applied to 3D printing technology in the manufacture of some aerospace precision parts. In the future, the application of 3D printing technology in aerospace will develop from ground processing, on-orbit assembly and on-orbit manufacturing to the direction of alien base construction.

Huijun Yi, "Application and Development of Resin Materials in 3D Printing

Ms. Yi Huijun, Senior Engineer, Project Manager of Resin Application Research Institute of Beijing Yanshan Petrochemical High-Tech Technology Co., Ltd. and Sinopec Beijing Yanshan Branch, introduced the application of resin materials in 3D printing and its development status. polymer materials used in 3D printing mainly include thermoplastics, photosensitive resins, rubber-like materials, composite materials, etc., and biomaterials, cellular materials, and DNA framework materials, Biomaterials, cellular materials, DNA framework materials, stem cell materials and other materials with great future prospects are also in the research and development stage, and there is a huge space for imagination. From the current application of China's 3D printing market, ordinary materials occupy half of the market, domestic self-developed mid-range material products accounted for about 40%, foreign high-quality imported consumables accounted for 10%. For the future application of 3D printing materials, such as Yanshan Petrochemical Resin Application Research Institute, such as the authoritative scientific research institutions will be committed to the development of more special-purpose consumable products for specific requirements of the development of more functional products, and the development of the future prospects for 3D printing materials. In view of the future application prospect of 3D printing materials, authoritative research institutes such as Yanshan Petrochemical Resin Application Research Institute will be committed to developing more special-purpose consumable products, developing more functional products for specific requirements, and improving the applicability of materials and 3D printing equipment.

Lu Chun: "3D Printing is All Around Us

Shenyang University of Aeronautics and Astronautics, Department of Aerospace Engineering, Professor Lu Chun pointed out that in the absence of contact with 3D printing before the processing of molds or parts, we usually habitually consider the use of CNC machining of milling processing, that is, subtractive molding process; and familiar with the 3D printing process, it will be used as a 3D printing technology as a way to solve our problems. For example, 3D printing cell phone case, with 3D printing manufacturing carbon fiber tee tube molding mold, manufacturing composite propeller molding mold and composite elevator rudder molding mold, etc. 3D printing makes our life and work easier.

For the future development of 3D printing, Prof. Lu Chun put forward several expectations:

Can have more excellent mechanical properties and heat resistance. Currently based on resin (plastic)-based 3D printing technology, more than low mechanical properties of PLA, ABS, PS and other resins as a printing material, low mechanical properties, poor temperature resistance, usually only used at room temperature, the ambient temperature is higher than 80 ℃ workpiece of the complete loss of mechanical properties. Many researchers have tried to modify the resin matrix. Such as through the addition of short-cut carbon fiber in the ABS material, the use of carbon fiber reinforced ABS resin, the mechanical properties of the prepared workpiece for the ABS material 30 times; in the resin to add ceramic materials, the use of resin as a carrier, after the row of glue, sintering, glazing and other processes, you can print the workpiece's temperature resistance to more than 1,000 ° C. At present, we and the domestic research institutes are also carrying out the study of this technology. Some progress has been made.

Have faster molding speed and higher molding precision. Have the functionality of sound, light, electricity, magnetism and so on. People's 3D printing materials will not only meet the needs of the molding process, but also put forward requirements for the functionality of the material. At present, the research results in this field are beginning to come out one after another. For example, the United States Northwestern University's research team developed a high graphene content can be 3D printing graphite, graphene content can reach 60% or more, it will be given to the printing material thermal conductivity, electrical conductivity. At present, the research and development of printable functional materials is in an accelerated stage of development, and I believe that more products will be available soon.

Finally, Prof. Lu shared the current research progress of his team. Its research and development of 3D printer and control software, the use of TCP control communication protocol, and high-precision servo motor closed-loop control, to effectively ensure that the printing process does not lose steps, the printer is currently working continuously and stably for more than 140 hours, there is no model misalignment, filament breakage problems. Its self-developed high-speed printer printing accuracy of 0.025mm, the fastest molding speed of 60mm / hour.

Liu Jianrong: "Research Progress on Titanium Alloys for Electron Beam Fused Wire Deposition".

Dr. Liu Jianrong from Institute of Metals, Chinese Academy of Sciences, introduced the research progress of titanium alloy wire for electron beam fusion deposition (EBRM). He pointed out that the metal material 3D printing technology needs to solve the four control problems: control "shape", that is, the shape, dimensional accuracy, equipment, process; control "sex", that is, the performance of the parts, material composition and heat treatment; control defects, that is, pores, porosity, cracking; control costs, that is, materials, processes, equipment, its technological advantages will eventually be realized. That is, material, process, equipment, its technical advantages can eventually be manifested.

Electron beam fused deposition is one of the four typical 3D printing technologies for metallic materials. It can realize rapid manufacturing of large structural blanks, filaments, and space in-orbit manufacturing in a vacuum environment. Domestic electron beam fused filament deposition technology has been developed relatively quickly since 2010, and the current technology chain is relatively complete, with balanced development and greater progress in equipment, materials, and process research, and preliminary applications in the aviation field. Titanium alloy is a more ideal 3D printing material, its weldability is good, low tendency of biocrystallization and segregation, cold cracking, thermal cracking phenomenon is not obvious, wide range of uses, physical properties of active, but the cost is high. titanium alloy filaments for EBRM, with the advantages of simple process and low cost. At present, several strength levels of titanium alloy wire have been developed in China to meet the needs of the current stage of development and application of EBRM technology. Domestic EBRM technology is at a relatively advanced level in the research and application of aerospace structural components.

For the current equipment "short board" problem, Dr. Liu Jianrong believes that we should actively support the breakthrough of the core technology of the equipment to occupy the strategic high point of the 3D printing industry. At the same time, we should promote the synergistic and rolling development of equipment, materials and processes, improve the equipment (functionality, stability) through the process, improve the overall technical level through the integration of materials, highlighting the advantages of 3D printing technology, and improve the competitiveness of the industry. The government, the association should also focus on the development of the industry, resource integration and effective use, and ultimately achieve win-win cooperation.

Fu Xinliang: "Innovation and Development of China's Body-in-White Equipment Industry in 2015

FAW Mould Manufacturing Co., Ltd. enterprise management and information technology room director, senior engineer Dr. Fu Xinliang shared the innovation and development of China's body-in-white equipment industry, and combined with the application of 3D printing in the field of automotive mold manufacturing proposed direction. According to the introduction, the current rapid development of China's body equipment manufacturing industry, thanks to years of technical cooperation with international advanced enterprises. The strong growth of China's body equipment manufacturing industry also makes the world's automotive equipment industry presents new vitality, for the world automotive industry to get rid of the financial crisis, re-entering the development track has made an important contribution. Now "Made in China 2025", "the new two integration" and other information technology and manufacturing in-depth integration of the main line of the new round of manufacturing upgrading has been kicked off. In the future, China's body equipment manufacturing will be deeply integrated into the global trend of manufacturing upgrading.

Dr. Fu Xinliang believes that 3D printing in the field of automotive mold manufacturing can be applied to mold inserts, mold foam solid type, small batch, trial mold or product parts, welding or rolling support block, checking fixture resin support block and other fields. For example, the application of mold inserts. The advantage is that the processing of small amount of retention, low processing costs, good surface quality, can be molded into complex shapes, the mechanical properties of the material to meet the use of requirements, but the printing cost is higher, longer cycle time, less batch.

On August 24th, Beijing, the autumn breeze was refreshing. The multimedia conference room of Petrochemical Research Institute located in PetroChina's innovation base had a warm atmosphere, where top domestic experts in refining and chemical technology gathered. Dr. Zong Guisheng, Chairman of Beijing SANDI Printing Technology Co., Ltd, Chairman of Shenzhen Seven Technology Co., Ltd, and Director of 3D Printing Special Committee of China Powder Metallurgy Technology Innovation Strategy Alliance, was invited to give a special report on "3D Printing Technology and Materials". Mr. Hu Jie, Vice President of Petrochemical Research Institute, Mr. Li Bohong, Deputy Director of Scientific Research Management Department, Mr. Huang Qiang, Director of Synthetic Resin Processing and Application Laboratory, Mr. Gao Fei, Director of Engineering Scale-Up and Process Laboratory, and Mr. Li Jingshan, Director of Party Affairs Office and Hospital Affairs Office, etc., attended the presentation, which was presided over by Dr. Xinshexuan, Deputy Chief Engineer of the Research Institute and Director of Key Laboratory of Synthetic Resin. Meanwhile, researchers from PetroChina Daqing Chemical Research Center and Lanzhou Chemical Research Center also participated in the communication and interaction of the presentation through video outside the site.

In the report, Dr. Zong Guisheng first analyzed the importance of 3D printing technology from the height of the national manufacturing strategy. He pointed out that in today's escalating global manufacturing challenges, manufacturing is changing faster than ever. In order to be undefeated in the competition, we need to improve efficiency, shorten the time to market, and enhance flexibility, and these needs have driven the development of smart manufacturing. 3D printing, as one of the core technologies of smart manufacturing, has the great potential to change the entire production industry, and is expected to become a key part of China's high-end manufacturing industry, and to promote the upgrading of China's manufacturing industry. At the same time, the global manufacturing countries have introduced their own competitive strategy: the U.S. Obama administration will be 3D printing as a stimulus to the manufacturing industry back to accelerate U.S. economic growth as an important "weapon"; Germany's "Industry 4.0" strategy to support the industrial sector. Germany's "Industry 4.0" strategy supports the research and development and innovation of a new generation of revolutionary technologies in the industrial field; domestically, the "National Additive Manufacturing Industry Development Promotion Plan (2015-2016)" puts forward the initial establishment of a more complete additive manufacturing industry system by 2016, the industry's sales revenue to achieve an average annual growth rate of 30% or more, the aerospace and other direct manufacturing areas to reach the international advanced level and other goals; the "Made in China 2025" plan also includes the following Made in China 2025" plan also made clear the realization of long-term constraints on the development of manufacturing key common technology breakthroughs, to enhance the overall competitiveness of China's manufacturing industry tasks and goals.

For the current situation of the 3D printing industry and the development prospects of the Chinese market, Dr. Zong Guisheng pointed out that the current 3D printing industry is growing at an average annual rate of about 30%, desktop 3D printers and the civilian market is growing rapidly, and the growth of services exceeds the growth of equipment. The global market size is expected to exceed $20 billion by 2020. 2013, China's 3D printing market size of 2 billion yuan, and the market potential is huge, it is expected that only sports, recreational products, furniture and other 3D printing direct manufacturing industry annual output value of up to one trillion dollars, the global industry scale will reach one trillion dollars.

After that, Dr. Zong Guisheng elaborated on the technical characteristics and application advantages of 3D printing from the perspectives of 3D printing equipment and process respectively. He said that 3D printing technology creates a new ability to produce items of various shapes and sizes, enabling engineers to design more complex products that could not be realized before. 3D printing is widely used in aerospace, automotive manufacturing, casting, medical, due to its advantages of manufacturing complex parts, product diversification without increasing costs, assembly-free, cloud manufacturing, zero-skill manufacturing, portable manufacturing, net molding, Civil and other fields of rapid prototyping, rapid manufacturing. In the future, if the use of 3D printing thinking to design and manufacture products, will bring a new era of design and manufacturing.

The National Additive Manufacturing Industry Development Advancement Plan (2015-2016), in particular, puts forward that efforts should be made to break through the special materials for additive manufacturing, and by 2016, the independent production of special materials will be basically realized to meet the needs of industrial development and application. The material and application of 3D printing is also a topic of particular concern to the experts here. In this regard, Dr. Zong Guisheng introduced that the polymer materials used in 3D printing mainly include thermoplastics, photosensitive resins, rubber materials, composite materials, etc., while biomaterials, cellular materials, DNA framework materials, stem cell materials and other materials with great future prospects are also in the research and development stage. Plastic is the most commonly used printing material in the field of 3D printing, and its common types are: ABS plastic, PLA (polylactic acid), nylon, PC, glass-filled polyamine, and through the mixing of different ratios of materials, nearly 120 kinds of soft and hard different new materials can be produced. From the current application of China's 3D printing market, ordinary materials occupy half of the world, domestic self-developed mid-range material products accounted for about 40%, foreign high-quality imported consumables accounted for 10%.

Dr. Zong Guisheng said that the 3D printing process parameter package of materials is an important value-added factor for printing materials. Talking about the application of materials in 3D printing, Dr. Zong put forward requirements and prospects for synthetic polymer materials and new application areas through the introduction and analysis of the properties and applications of several typical common materials for 3D printing.

Finally, for the current development of the domestic 3D printing industry is faced with technology, products, R & D, applications, standards and other challenges, Dr. Zong Guisheng suggests that through enterprise-led, talent gathering, government support and a high degree of marketization to deal with. Government departments and industry enterprises should change their thinking, from the previous respective, fragmented R & D, sales of lone combat, slow natural growth of the development model, and gradually transformed into a platform for the operation of the overall planning, R & D, project R & D, synergistic, mergers and acquisitions of the growth, and through the industry associations to build a professional platform, technical exchanges, participation in the development of industry standards, and ultimately through the integration of resources to achieve a win-win cooperation.

[About China Petroleum and Chemical Research Institute]

Petrochemical Research Institute (PRI) is a research institute directly under PetroChina Company Limited, which consists of 9 research institutes and exercises operational leadership over 4 chemical research centers in Lanzhou, Daqing, Jilin and Liaoyang, and centrally undertakes the tasks of PetroChina's R&D in refining and chemical technology. Petrochemical Research Institute is the decision support and production technology service center for PetroChina's refining business, high-tech R&D center and high-level refining science and technology talent training center, and its development goal is to be a "first-class, internationally renowned" refining technology research institute, providing technical support for the development of PetroChina's refining business. Its main functions are: tracking the international refining and chemical technology development trend, providing strategic decision-making support for the company's downstream business development; based on the company's development planning and production needs, proposing and undertaking major refining and chemical technology research, basic research, applied research, and advanced reserve technology research projects; organizing and carrying out domestic and foreign research and development cooperation in refining and chemical technology, and doing a good job in the digestion, absorption and re-innovation of the key technologies and introduced technologies for the leading products; being responsible for the pilot testing of major technologies, and the development of the refining and chemical technology research and development center. It is also responsible for pilot and industrial tests of major technologies, engineering research of refining and chemical technologies, promotion of scientific research results, technical services and technical training.

[About Beijing SANDI Printing Technology Co.

Beijing Three Emperor Printing Technology Company (3DP Technology, Inc.) is a high-tech holding company focusing on the research, development, production, and sales of 3D printing systems (equipment, materials, processes, software) and their applications. Founded by one of the world's first 3D printing doctors, China's first high-tech enterprise focusing on 3D printing, developed China's first industrial 3D printer in 1993, rapid prototyping machine, won the Beijing invention gold medal. The company has independent intellectual property rights, the main products and services: industrial 3D printers, 3D printing materials, and everything printing services. At present, the company has more than 140 high-end equipment users and more than 100 processing service users, the market application is mainly in the aviation, aerospace, automotive, and medical fields. (Text/Jiayu)

In order to revitalize the northeastern region and other old industrial bases, accelerate the development of China's equipment manufacturing industry, by the Ministry of Commerce, the National Development and Reform Commission and other ministries and commissions, Shenyang Municipal People's Government to host the "2015 14th China International Manufacturing Expo" will be held on September 1-5 in Shenyang International Exhibition Center. This exhibition has set up a national high-tech, 3D printing, industrial design, equipment manufacturing and other eight special exhibition areas. The same period will also be held "3D printing and enterprise transformation and upgrading" and other forums, seminars, technical exchanges and business cooperation.

First 3D Printing Exhibition

In recent years, from the U.S. Obama administration will be listed as 3D printing to stimulate the return of the manufacturing industry, accelerate the U.S. economic growth of an important "weapon", to Germany's "Industry 4.0" strategy to support the development of a new generation of revolutionary technologies in the field of industrial R & D and innovation, and then the domestic "Made in China 2025" plan clearly to enhance the overall competitiveness of China's manufacturing sector tasks and goals. Made in China 2025" plan clearly enhance the overall competitiveness of China's manufacturing industry tasks and goals, the global manufacturing countries have introduced competitive strategies.

At this historic critical period of transformation and upgrading of China's manufacturing industry and accelerating the transformation of the mode of development, advanced manufacturing technology with digitalization and intelligence as the core will drive the innovation of products, manufacturing technology and industrial model, profoundly changing the production mode of manufacturing industry and industrial form, China's manufacturing industry has ushered in the perfect time to realize the leap.

Therefore, this year's China International Manufacturing Expo has set up a 3D printing technology and equipment exhibition area for the first time, and has gained strong support from more than 50 3D printing enterprises from home and abroad and actively participated in the exhibition. Ltd., Gain Science and Technology Development Co., Ltd., Beijing SANDI Printing Technology Co., Ltd. and Shenzhen Seven Technology Co., Ltd. will jointly present 3D printing exhibition with their well-known brands, September 1-5, please pay attention to the E2C15 booth.

Liaoning Juzi Industrial Co., Ltd. has been rooted in Liaoning since 2005, and in 2006, with the construction of new industrial park and mold manufacturing industry as the core, and in line with the development concept of "science and technology leading, innovation-driven", it constructed and successfully operated Shenyang Taizhou Juzi Plastic Mold City, and won the honorary title of "2009 National Zhejiang Business Top Ten New Business Models" and other honorary titles. 2009 National Zheshang Top Ten New Business Models" and other honorary titles. It has made remarkable achievements in promoting the new development mode of industrial park and the development of Liaoning mold industry and machinery manufacturing industry. Over the past ten years, Jusco has been rooted in Northeast China, formed a core team full of passion and innovative spirit, and established the development strategy of science and technology as the driving force and industrial synergy and innovation.

Gain Technology Development Co., Ltd. is a solution provider specializing in 3D printing related equipment development and system technology. It mainly provides 3D printing equipment, equipment spare parts, equipment after-sales service, printing materials, 3D printing related software, industrial design, reverse engineering and other 3D printing related system solutions. Its 500-square-meter 3D printing innovation experience center serves as an offline technical service platform for 3D printing, and is committed to creating an O2O business model combining online and offline 3D printing. Its product GN FDM desktop 3D printer has good printing accuracy and speed, which can meet the needs of modern education, innovation and entrepreneurship, industrial design and other areas that require low-cost, high-efficiency customized model production, unique technology can be manually without intermittent material change, to achieve layered colorful prints, and the equipment has excellent working stability.

Ltd., a subsidiary of Beijing SANDY Printing Technology Co., Ltd. and a veteran of industrial 3D printing in China, will bring its SLS rapid prototyping machine to the exhibition this time. As one of the earliest enterprises in China to research and develop 3D printing technology, Beijing Longyuan Auto Molding has been playing the role of practitioner and leader of 3D printing industrialization since 1994 when it successfully developed China's first Selective Laser Powder Sintering (SLS) rapid prototyping machine, and has been devoted to the industrialization of rapid prototyping applications and processing services. Meanwhile, in the application of metal 3D printing, Longyuan has successfully passed the acceptance of the expert group of "Zhongguancun Industrial Technology Alliance Major Application Demonstration Project", and has the R&D and production capacity of direct metal 3D printing equipment. At present, it has more than 400 equipment and processing service users, spreading over aerospace, shipbuilding, automobile manufacturing, electronics, casting, medical care, culture and art and other fields, research institutes and colleges and universities.

Domestic civilian 3D printing innovation pioneer enterprise Shenzhen Seven Technology Co., Ltd. under the Everything Print brand will be on the show floor to demonstrate the "everything is connected, everything print" 3D printing ecosystem. The Arts maker Internet of Things desktop 3D printer is based on the "Everything Printing Network".www.wanwudayin.comThe service platforms of "Arts maker" and "Printing APP" allow users to independently choose the nearest 3D printer to their terminal or the one they want to complete the printing after submitting their printing needs online through the Internet. Everything prints (Arts maker) Internet of Things desktop 3D printer has completely independent intellectual property rights, its appearance is simple, stylish, good human-machine dialogue experience is very pro-people, accurate positioning, smooth filament and other stable performance to ensure excellent print quality, support for remote data transmission, remote printing, big data throughput, multi-compatible operating system to make the operation more simple and convenient, modular design Modular design makes maintenance and cleaning more convenient and humanized.

"3D Printing and Enterprise Transformation and Upgrading" Summit Forum and Liaoning 3D Printing Association Establishment Meeting

The deep integration of new-generation information technology and manufacturing will promote profound changes in the manufacturing model, production organization and industrial form, and intelligence and servitization will become a new trend in the development of manufacturing. Virtualization technology, 3D printing, industrial Internet, big data and other technologies will reconstruct the manufacturing technology system. In this situation, how should China's manufacturing grasp the opportunity to promote structural adjustment and transformation and upgrading? How to shape new advantages in international competition and seize the first opportunity for the future development of manufacturing industry?

During the same period, "3D Printing and Enterprise Transformation and Upgrading" Summit Forum and the Founding Conference of Liaoning 3D Printing Association will be held at 13:30 on September 2 at Shenyang International Convention and Exhibition Center, which is hosted by Liaoning 3D Printing Industry Association and organized by Liaoning Juzi Industry Co. The conference will be held at 13:30 on September 2 in Shenyang International Convention and Exhibition Center, which will be attended by experts, scholars and entrepreneurs from the 3D printing industry at home and abroad. Dr. Zong Guisheng, Chairman and CEO of Beijing SANDI Printing Technology Co., Ltd, Chairman of Shenzhen Seven Technology Co., Ltd, and Director of 3D Printing Committee of China Powder Metallurgy Industry Technology Innovation Strategy Alliance, will be the moderator of the forum.

In today's world of escalating manufacturing challenges, manufacturing is changing faster than ever before. In order to remain undefeated in the competition, we need to improve efficiency, shorten time-to-market, and enhance flexibility, and these demands are driving the development of smart manufacturing. 3D printing, as one of the core technologies of smart manufacturing, is expected to become a key aspect of China's high-end manufacturing industry and promote the upgrading of China's manufacturing industry. As the cradle of new China's industry, the old industrial base in Northeast China has made historic and significant contributions to the country's reform, opening-up and modernization by building an independent and complete industrial system and national economic system. In the country to actively promote and implement the strategy of revitalization of the old industrial bases in the northeast region, today, 3D printing, the world's advanced manufacturing technology will bloom in China's old industrial bases what glory? Let us wait and see. (Article/Jiayu)

In order to revitalize the northeastern region and other old industrial bases, accelerate the development of China's equipment manufacturing industry, by the Ministry of Commerce, the National Development and Reform Commission and other ministries and commissions, Shenyang Municipal People's Government to host the "2015 14th China International Manufacturing Expo" will be held on September 1-5 in Shenyang International Exhibition Center. This exhibition has set up a national high-tech, 3D printing, industrial design, equipment manufacturing and other eight special exhibition areas. The same period will also be held "3D printing and enterprise transformation and upgrading" and other forums, seminars, technical exchanges and business cooperation.

First 3D Printing Exhibition

In recent years, from the U.S. Obama administration will be listed as 3D printing to stimulate the return of the manufacturing industry, accelerate the U.S. economic growth of an important "weapon", to Germany's "Industry 4.0" strategy to support the development of a new generation of revolutionary technologies in the field of industrial R & D and innovation, and then the domestic "Made in China 2025" plan clearly to enhance the overall competitiveness of China's manufacturing sector tasks and goals. Made in China 2025" plan clearly enhance the overall competitiveness of China's manufacturing industry tasks and goals, the global manufacturing countries have introduced competitive strategies.

At this historic critical period of transformation and upgrading of China's manufacturing industry and accelerating the transformation of the mode of development, advanced manufacturing technology with digitalization and intelligence as the core will drive the innovation of products, manufacturing technology and industrial model, profoundly changing the production mode of manufacturing industry and industrial form, China's manufacturing industry has ushered in the perfect time to realize the leap.

Therefore, this year's China International Manufacturing Expo has set up a 3D printing technology and equipment exhibition area for the first time, and has gained strong support from more than 50 3D printing enterprises from home and abroad and actively participated in the exhibition. Ltd., Gain Science and Technology Development Co., Ltd., Beijing SANDI Printing Technology Co., Ltd. and Shenzhen Seven Technology Co., Ltd. will jointly present 3D printing exhibition with their well-known brands, September 1-5, please pay attention to the E2C15 booth.

Liaoning Juzi Industrial Co., Ltd. has been rooted in Liaoning since 2005, and in 2006, with the construction of new industrial park and mold manufacturing industry as the core, and in line with the development concept of "science and technology leading, innovation-driven", it constructed and successfully operated Shenyang Taizhou Juzi Plastic Mold City, and won the honorary title of "2009 National Zhejiang Business Top Ten New Business Models" and other honorary titles. 2009 National Zheshang Top Ten New Business Models" and other honorary titles. It has made remarkable achievements in promoting the new development mode of industrial park and the development of Liaoning mold industry and machinery manufacturing industry. Over the past ten years, Jusco has been rooted in Northeast China, formed a core team full of passion and innovative spirit, and established the development strategy of science and technology as the driving force and industrial synergy and innovation.

Gain Technology Development Co., Ltd. is a solution provider specializing in 3D printing related equipment development and system technology. It mainly provides 3D printing equipment, equipment spare parts, equipment after-sales service, printing materials, 3D printing related software, industrial design, reverse engineering and other 3D printing related system solutions. Its 500-square-meter 3D printing innovation experience center serves as an offline technical service platform for 3D printing, and is committed to creating an O2O business model combining online and offline 3D printing. Its product GN FDM desktop 3D printer has good printing accuracy and speed, which can meet the needs of modern education, innovation and entrepreneurship, industrial design and other areas that require low-cost, high-efficiency customized model production, unique technology can be manually without intermittent material change, to achieve layered colorful prints, and the equipment has excellent working stability.

"3D Printing and Enterprise Transformation and Upgrading" Summit Forum and Liaoning 3D Printing Association Establishment Meeting

The deep integration of new-generation information technology and manufacturing will promote profound changes in the manufacturing model, production organization and industrial form, and intelligence and servitization will become a new trend in the development of manufacturing. Virtualization technology, 3D printing, industrial Internet, big data and other technologies will reconstruct the manufacturing technology system. In this situation, how should China's manufacturing grasp the opportunity to promote structural adjustment and transformation and upgrading? How to shape new advantages in international competition and seize the first opportunity for the future development of manufacturing industry?

During the same period, "3D Printing and Enterprise Transformation and Upgrading" Summit Forum and the Founding Conference of Liaoning 3D Printing Association will be held at 13:30 on September 2 at Shenyang International Convention and Exhibition Center, which is hosted by Liaoning 3D Printing Industry Association and organized by Liaoning Juzi Industry Co. The conference will be held at 13:30 on September 2 in Shenyang International Convention and Exhibition Center, which will be attended by experts, scholars and entrepreneurs from the 3D printing industry at home and abroad. Dr. Zong Guisheng, Chairman and CEO of Beijing SANDI Printing Technology Co., Ltd, Chairman of Shenzhen Seven Technology Co., Ltd, and Director of 3D Printing Committee of China Powder Metallurgy Industry Technology Innovation Strategy Alliance, will be the moderator of the forum.

In today's world of escalating manufacturing challenges, manufacturing is changing faster than ever before. In order to remain undefeated in the competition, we need to improve efficiency, shorten time-to-market, and enhance flexibility, and these demands are driving the development of smart manufacturing. 3D printing, as one of the core technologies of smart manufacturing, is expected to become a key aspect of China's high-end manufacturing industry and promote the upgrading of China's manufacturing industry. As the cradle of new China's industry, the old industrial base in Northeast China has made historic and significant contributions to the country's reform, opening-up and modernization by building an independent and complete industrial system and national economic system. In the country to actively promote and implement the strategy of revitalization of the old industrial bases in the northeast region, today, 3D printing, the world's advanced manufacturing technology will bloom in China's old industrial bases what glory? Let us wait and see. (Article/Jiayu)

On August 13, 2015, "3D Printing and China's Smart Manufacturing" Summit Forum was held in Shenzhen Convention and Exhibition Center. Experts, scholars and entrepreneurs from home and abroad conducted in-depth analysis and discussion on the development of 3D printing industry, materials, market applications and so on. This forum was organized by Shenzhen Overseas Chinese Think Tank Research Institute, China Powder Metallurgy Industry Technology Innovation Strategic Alliance, Shenzhen Seven Technology Co., Ltd. and received extensive attention from people from all walks of life and the media.

Dr. Zong Guisheng, Director of 3D Printing Professional Committee of China Powder Metallurgy Industry Technology Innovation Strategy Alliance, Chairman of SANTI Printing Technology Co.

Dr. Zong Guisheng, Director of 3D Printing Professional Committee of China Powder Metallurgy Industry Technology Innovation Strategy Alliance, Chairman of SANDI Printing Technology Co., Ltd. and Chairman of Shenzhen Seven Technology Co., Ltd. hosted the forum and delivered a keynote speech. Dr. Zong Guisheng said that at present, the global manufacturing challenges are escalating and the manufacturing industry is changing faster than ever. In order to stay in the competition, we need to improve efficiency (especially energy and resource efficiency), shorten time-to-market (shorter development time, ability to manufacture complex products, ability to quickly access and analyze big data), and increase flexibility (large number of personalized products, rapidly changing markets, high productivity requirements), which drives the development of smart manufacturing.

The combination of ICT technology and manufacturing gives rise to smart manufacturing. Walking into a future smart manufacturing factory, you can see a variety of independent devices (e.g., 3D printing) that are connected, constantly open, intelligent, software- and data-controlled; machine-to-machine and machine-to-product communication is all about human interaction; the Internet of Things (IoT) triggers and provides information and data for decision-making; information is processed and transmitted in real time; and staff members can make decisions on their own or as a group (societal group decision-making), and the entire industrial ecosystem is going to The entire industrial ecosystem will change profoundly.

3D printing, one of the core technologies of smart manufacturing, has a huge potential to transform the entire production industry. It creates a whole new ability to produce items of various shapes and sizes, enabling engineers to design more complex products that could not be realized before.3D printing is widely used in rapid prototyping in aerospace, automotive manufacturing, foundry, medical, civil and other fields due to its advantages of manufacturing complex parts, product diversification without increasing costs, assembly-free, cloud manufacturing, zero-skill manufacturing, portable manufacturing, net molding, etc. , rapid manufacturing. Looking to the future, we apply 3D printing thinking to design and manufacture products, and embrace intelligent manufacturing.

The combination of 3D printing devices and the Internet has led to innovations in business models. For example, online platforms that provide 3D printing services and transactions - Shapeways, Ponoko, i.materialise, Everything Print (www.wanwudayin.com), etc. Through these sites, users can purchase design models, order 3D printed products, or open their own stores to sell 3D printed products, designs or materials. This new business model is called D2C - Designer to Customer, and it not only fulfills an individual's desire to create, but also translates into commercial profitability, which in turn will surely further drive the growth of personal 3D printing demand. What Chris Anderson calls "creativity" is the key to the success of 3D printing. Anderson said the "creators" era is step by step into reality.

Ms. Lu Shengping, Chairwoman of Liaoning Juzi Industry Co., Ltd. and Founder of Shenyang Gain Technology Co.

Ms. Lu Shengping, Chairwoman of Liaoning Juzi Industrial Co., Ltd. and Founder of Shenyang Gain Technology Co., Ltd. made an in-depth elaboration and analysis on the application and development of 3D printing technology in modern education and innovation and entrepreneurship. She pointed out that the application of 3D printing in the field of modern education helps to improve the level of innovation and creativity and hands-on ability of students. For example, through the 3D printing creative teaching tools to improve student participation in the curriculum, so that the teaching knowledge materialization; through the school-based, experiential, innovative, special and other forms of curriculum, the establishment of school characteristics of education, to promote the popularization of 3D printing technology to enhance the problem-solving ability of students. In addition, 3D printing in the field of innovation and entrepreneurship in the application of great advantages: can improve the efficiency of customization, reduce the design, research and development, trial production, customization and other aspects of the cost of design, R & D, research and development, production of the trinity, and at the same time to avoid the leakage of the design of the sketches, to achieve the effective protection of intellectual property rights. In the future, 3D printing will be fully popularized in domestic primary and secondary schools, and gradually from the school into the family.

Ms. Li Lei, Senior Engineer, Project Manager, Resin Application Research Institute, Beijing Yanshan Petrochemical High-Tech Technology Co.

Ms. Li Lei, Senior Engineer, Project Manager of Resin Application Research Institute of Beijing Yanshan Petrochemical High-Tech Technology Co., Ltd. and Sinopec Beijing Yanshan Branch, introduced the application and development status of resin materials in 3D printing. polymer materials used in 3D printing mainly include thermoplastic plastics, photosensitive resins, rubber materials, composites and so on, while materials with great future prospects such as biomaterials, cellular materials, DNA framework materials and stem cell materials are also in the research and development stage. Biomaterials, cellular materials, DNA framework materials, stem cell materials and other materials with great future prospects are also in the research and development stage, and there is a huge space for imagination. From the current application of China's 3D printing market, ordinary materials occupy half of the market, domestic self-developed mid-range material products accounted for about 40%, foreign high-quality imported consumables accounted for 10%. For the future application of 3D printing materials, such as Yanshan Petrochemical Resin Application Research Institute, such as the authoritative scientific research institutions will be committed to the development of more special-purpose consumable products for specific requirements to develop more functional products. In view of the future application prospect of 3D printing materials, authoritative research institutes such as Yanshan Petrochemical Resin Application Research Institute will be committed to developing more special-purpose consumable products, developing more functional products for specific requirements, and improving the applicability of materials and 3D printing equipment.

Dr. Zifu Li, member of 3D Printing Professional Technical Committee of China Powder Metallurgy Technology Innovation Strategy Alliance, Deputy General Manager of Shenzhen Seven Technology Co.

Dr. Zifu Li, member of 3D Printing Professional Technical Committee of China Powder Metallurgy Technology Innovation Strategy Alliance, deputy general manager of Shenzhen Seven Technology Co. Ltd, and technical director of Beijing Longyuan Automatic Forming System Co. Ltd, analyzed the application key technology and development trend of metal 3D printing. Data show that in 2014, the global additive manufacturing market scale is about 4.1 billion U.S. dollars, metal 3D printing equipment amounted to 546 units, showing a high-speed growth trend; the direct printing of functional parts will become the main application direction in the future. Metal 3D printing, as a high-end additive manufacturing technology capable of directly manufacturing high-performance metal functional parts in three dimensions, has been planned and laid out from the national science and technology development strategy level. At present, it has been widely used in aerospace, automotive, medical and other fields. For example, Beijing Longyuan molding in June 2015 successfully passed the "Zhongguancun Industrial Technology Alliance major application demonstration project" expert group acceptance, with direct metal 3D printing equipment development and production capacity.

High-quality metal powder material is the realization of high-performance products printed on the premise of the foundation, and the current metal additive manufacturing equipment monopolized by foreign high-end products, due to the existence of equipment and materials adaptability, which in turn formed a monopoly on the supply of foreign metal powder material. Foreign brands of metal powder is expensive, long supply cycle, if it involves sensitive materials, but also by foreign export restrictions. Therefore, the realization of additive manufacturing metal powder localization is imperative.

Looking forward to the future development of metal additive manufacturing, Dr. Li said that in terms of materials and processes, it is necessary to improve the diversity of materials, develop domestically produced metal powder materials with cost advantages, strengthen the in-depth fusion of additive manufacturing technology and traditional material molding technology, and set up a large database integrating the design and preparation of powder materials, optimization of the additive manufacturing process, and optimization of the subsequent processing process, etc.; in terms of equipment systems, it will be Tend to molding space is bigger, additive manufacturing process monitoring system is more intelligent, equipment specialization, "metal additive manufacturing +" intelligent manufacturing mode, etc.; application, will tend to the direct manufacturing of functional parts, medical and health fields, automotive and aerospace fields.

Dr. Xie Yanjun, Director of Academic Department, China Steel Research Technology Group Corporation, China Powder Metallurgy Industry Technology Innovation Strategic Alliance

Dr. Xie Yanjun, Director of Academic Department of China Steel Research Technology Group Corporation and China Powder Metallurgy Industry Technology Innovation Strategic Alliance, analyzed and introduced the development status of metal additive manufacturing (3D printing). He said that metal additive manufacturing is an important part of additive manufacturing technology (3D printing), which has great advantages in solving the problems of difficult-to-machine materials, complex structures and rapid manufacturing in industrial production. As the most technically difficult and fastest-growing market potential and growth area in the additive manufacturing industry, laser additive manufacturing of metal parts has high strength, dimensional accuracy, watertightness and lightweight characteristics, and has been applied in aerospace, defense, medical, automotive, electronics and other fields.

For the current development mode of "heavy equipment, light materials, light process" in the field of additive manufacturing in China, Dr. Xie Yanjun believes that the development of additive manufacturing technology is a whole industry chain work combining equipment, materials, process and application, and in addition to increasing the investment in research and development and overcoming technical barriers at the national level, it is also necessary to organize the industry alliance to give full play to the advantages of each unit and integrate resources to form a platform development mode, which is of great significance to the rapid development of China's additive manufacturing industry. In addition to increasing R&D investment and attacking technical barriers at the national level, it also needs to be organized by the industry alliance, which will give full play to the advantages of each unit, integrate resources, and form a platform development mode, which is of great significance to the rapid development of China's additive manufacturing industry. (Text/Jiayu)

Conversation with Entrepreneur I: Zong Guisheng, Chairman of the Board, SANDI Printing Technology Co.

Zong Guisheng: As a student out of entrepreneurship, including some from the teacher now retired to start their own business, will encounter some views, in the face of these various arguments and views, how did you deal with it?

Liu Jiren: At that time in fact should be very entangled. The school called me general manager, I went back at night because of this can not sleep. But I later figured out that you live for your own dreams? Or for others? In the beginning, you want to get everyone's applause too much, you may lose the goal of struggle; and you stick to the goal of struggle, if you go well, then you will also get (applause) in the future. So I think it's more important to love yourself and your dreams than to love others.

Zong Guisheng: So it's important to have a firm, clear goal to rush towards, and leave the rest alone?

Liu Jiren: Yes.

Zong Guisheng: The core technology of the third industrial revolution is ICT technology, that is, information and communication technology. I've noticed that Neusoft has a lot of solutions in manufacturing, and now there's not yet, for example, like an MIS system. Isn't it an appropriate time that we should start to have our own national system?

Liu Jiren: It will have two parts in the future. One is an information technology system for knowledge-based manufacturing. I think China's manufacturing enterprises in the past is very remarkable, to control this cost so low, which has a lot to do with their use of a lot of information technology in the past 20 years. How can manufacturing and communications, software and other IT can be combined to enhance its added value, and the space for this, I think, is still just beginning. For example, how can we have robots for home care at home? Then this one has technology for recognition and communication; it has assistive technology, it might help the elderly to come to the police, and this one is artificial intelligence, large-scale big data and cloud computing. So I think this must be a new beginning. Germany called "Industry 4.0", China called "Internet +", heralding a cross-border integration, the integration of technology, is a trend of future development. (Source: Tencent Finance "Choice")

In May 2015, the technical support of the marketing department of Beijing Universal Precision Technology Co., Ltd, the controlling subsidiary of SANDY Printing Technology Co., Ltd, was invited to support the paraplegic support project of Guangxi Disabled Persons' Federation in Liuzhou, participating in the whole process of patient screening in the countryside, pre-assessment, RGO production and guidance of rehabilitation training for the patients in the later stage, which was highly evaluated by Liuzhou Municipal Government, and gained the unanimous thanks and praise from the families of the patients.

It is reported that fitting 50 poor paraplegic disabled people with braces free of charge and guiding them in rehabilitation training is one of the practical projects for the people of Liuzhou Municipal Government in 2015. In order to ensure quality and efficiency, Wang Xiao, a well-known domestic orthopedist from Beijing Global Jingbo Rehabilitation Auxiliary Technology Co., Ltd. was specially hired to provide technical guidance throughout the whole process.

Universal Precision Orthopedic Surgeon Wang Xiao evaluates and examines the patient's physical condition.

Assistive technology technician taking cast samples from patients