北京三帝科技股份有限公司(以下简称“三帝科技”)近日宣布,其自主研发的1.8米大尺寸砂型3D打印设备3DPTEK-J1800成功中标一汽铸造有限公司黑色铸造事业部自动化改造项目。该项目将落地一汽铸造无锡分公司,标志着双方在推动汽车制造领域3D打印数字化生产应用方面迈出坚实一步。

此次合作的核心设备——3DPTEK-J1800,是三帝科技3D铸造整体解决方案的主力机型,集多项创新技术于一身:高速振动铺粉技术,显著提升铺粉效率和均匀性;高性能成型工艺与智能算法,保障设备运行高效、操作简便;超大成型尺寸(1800×1000×700 mm)与高精度(最高±0.3mm),满足大型、复杂砂模的快速制造需求;双缸交替打印与负压供墨系统,实现设备连续、稳定生产。该设备专为航空航天、汽车、船舶泵阀、工程机械等领域的大尺寸砂模快速制造及中小批量铸件生产而设计,能有效满足复杂样件研发与工业化生产需求。

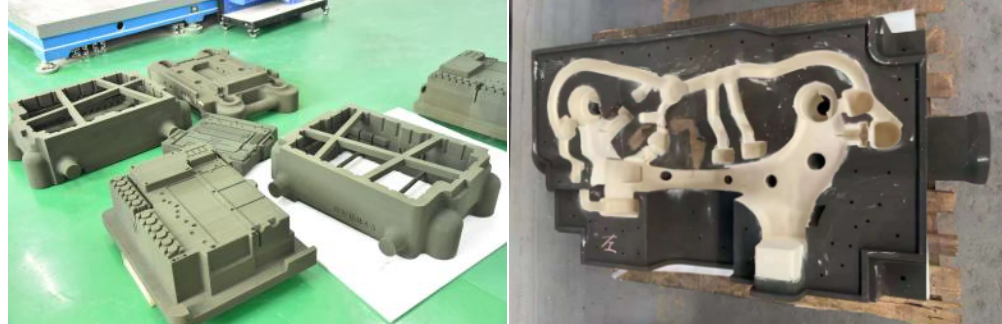

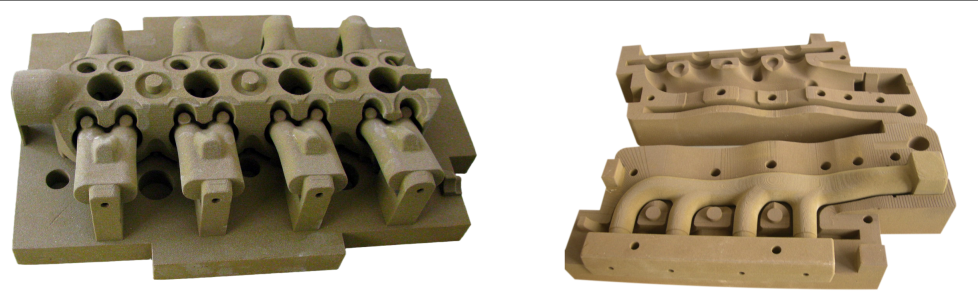

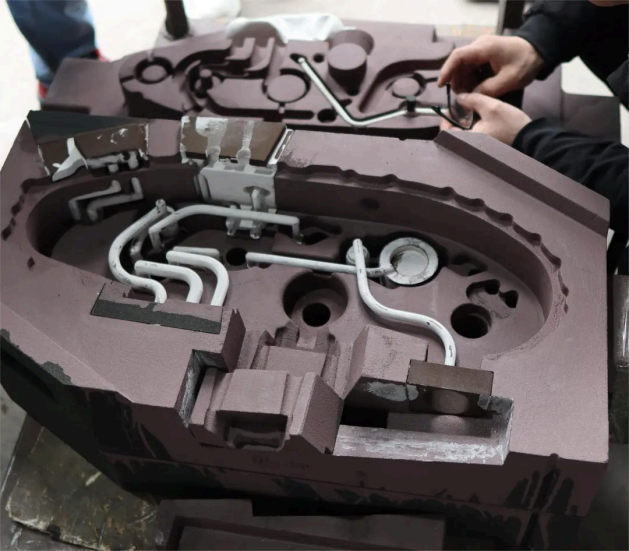

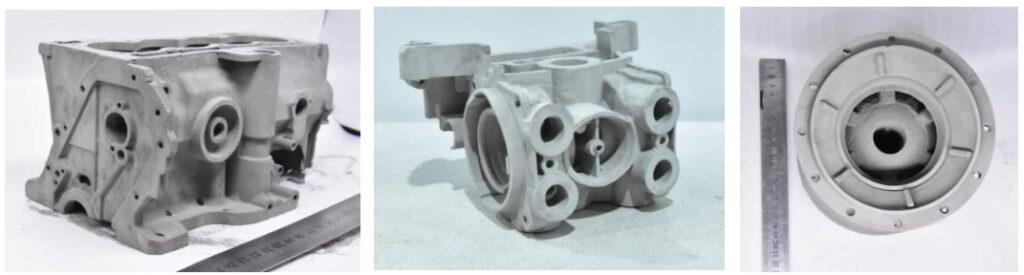

图:3DP砂型案例

砂型3D打印技术赋能汽车制造升级

在汽车制造领域,砂型3D打印技术正发挥着日益重要的作用:1. 提升设计自由度与创新效率,快速制造发动机、底盘件等设计原型,加速验证优化,缩短研发周期;2. 攻克复杂精密零件制造难题,如泵体、闭式叶轮等传统工艺难以加工的部件,免去脱模限制,提升零件性能;3. 实现高效灵活的小批量定制,无需昂贵模具,快速响应市场需求;4. 保障核心部件铸造质量,直接打印高精度功能性砂芯(如发动机缸体内部结构),确保铸件质量。

三帝科技已凭借其成熟的砂型3D打印技术,为众多国内外车企提供了涵盖电机壳、轻量化车架、壳体、缸体/缸盖、排气管等系列化产品的解决方案,尤其在汽车动力总成、传动部件及精密结构件制造方面积累了丰富经验。

图:3DP、SLS汽车砂型案例

强强联合,共塑行业标杆

一汽铸造作为中国汽车制造工业的领军企业,长期致力于高品质汽车零部件、工程机械铸件等的研发与生产,并积极推动智能制造转型。此次项目主体一汽铸造无锡分公司,专注于中重型卡车发动机核心铸件(如缸体、缸盖、曲轴、飞轮等)的研发与生产,在薄壁高强度铸铁生产技术领域处于国内领先地位。双方合作渊源已久,早在2008年,一汽铸造便引入了三帝科技旗下隆源成型的SLS激光砂型打印设备用于发动机缸体、缸盖等复杂产品的快速试制。

三帝科技项目负责人表示:“此次中标是对三帝科技3D铸造技术实力与服务能力的充分肯定。我们将全力保障项目顺利实施,助力一汽铸造提升新品开发速度、改进产品质量和生产效率,共同将该项目打造成汽车制造领域3D打印数字化生产的行业应用典范。”

随着汽车产业向智能化、轻量化、定制化方向发展,3D打印技术正深度融入汽车制造从概念设计、研发试制到生产制造、维修服务的全生命周期。三帝科技与一汽铸造的此次合作,将进一步推动3D打印技术在汽车核心零部件制造领域的规模化应用,为行业高质量发展注入新动能。

[About SANDI TECHNOLOGY

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national specialized, special and new "small giant" enterprise, and a typical application scenario supplier of additive manufacturing of the Ministry of Industry and Information Technology (MIIT). At the same time has laser and binder jet 3D printing equipment and materials technology and application process, business covers the development and production of 3D printing equipment, 3D printing raw materials development and production, 3D printing process technology support services, rapid finished parts manufacturing services, etc., the establishment of a complete 3D printing additive manufacturing industry chain, which is widely used in aerospace, electric power and energy, ships, pumps and valves, automobiles, rail transportation, industrial machinery, 3C electronics, rehabilitation and transportation, and industrial machinery, 3C electronics, and industrial machinery, and industrial machinery, and industrial machinery, and industrial machinery, and 3C electronics, and rehabilitation and transportation, industrial machinery, 3C electronics, rehabilitation and medical treatment, education and scientific research, sculpture and cultural creation and other fields.

In the field of high-end equipment manufacturing, the precision casting of key components has been a bottleneck that restricts the improvement of product performance. Whether it is the complex flow channel of ship pumps and valves, the high temperature resistant structure of aerospace power components, or the precision cavity of industrial machinery, the traditional casting process is faced with common challenges such as long mold development cycle, high cost, and difficulties in molding complex structures. Beijing SANDI Technology Co., Ltd (referred to as "SANDI Technology") unique 3DP + SLS composite sand casting technology, is a series of industry challenges for this breakthrough solution.

The process creatively combines the advantages of two 3D printing technologies: the 3DP process for making high-precision outer molds, and the SLS process for molding complex inner cavities or fine piping cores. This combination of technologies not only realizes the structural complexity that is hard to reach by traditional processes, but also improves the strength of the sand core to 4-6MPa, which is much higher than the 1.5-2.5MPa level of traditional processes. In practical applications, this process has been successfully used in the high-precision manufacturing of complex structural parts for ship pumps and valves, aerospace power components, etc.

Recently, Xinxin Casting, a subsidiary of SANDI Technology, successfully delivered a batch of highly difficult cast steel pump bodies for an industrial machinery customer. The structure of this batch of pump body is extremely complex, including several narrow inner cavities of only 2-3 millimeters in width, and need to withstand a casting temperature of up to 1750°C. The traditional casting method requires a production cycle of nearly 60 days. The traditional casting method requires nearly 60 days of production cycle, while the use of 3DP + SLS composite process, Xinxin casting only 20 days to complete the delivery of 10 products, in order to ensure the quality of the same time, the efficiency of the traditional process has increased by 3 times.

Previously, the technical reliability of the composite process has been verified in the aerospace field. The aircraft engine parts manufactured by SANDI Technology using this process have been successfully selected as a typical application list of additive manufacturing by the Ministry of Industry and Information Technology. While solving the complex oil circuit sand core printing problems, the process effectively overcomes the deformation of the traditional sand mold in the temperature return process, providing a new technical path for high-precision casting.

Supporting this innovative process is a system of 3D printing equipment independently developed by SANDI Technology. Among them.3DP Sand PrinterThe series is equipped with 400dpi ultra-fine printhead and precision motion control system, which can realize the highest printing accuracy of ±0.3mm. Through piezoelectric inkjet technology + high-resolution inkjet system + special binder, it realizes high-speed, precise and integrated molding of complex structural parts.

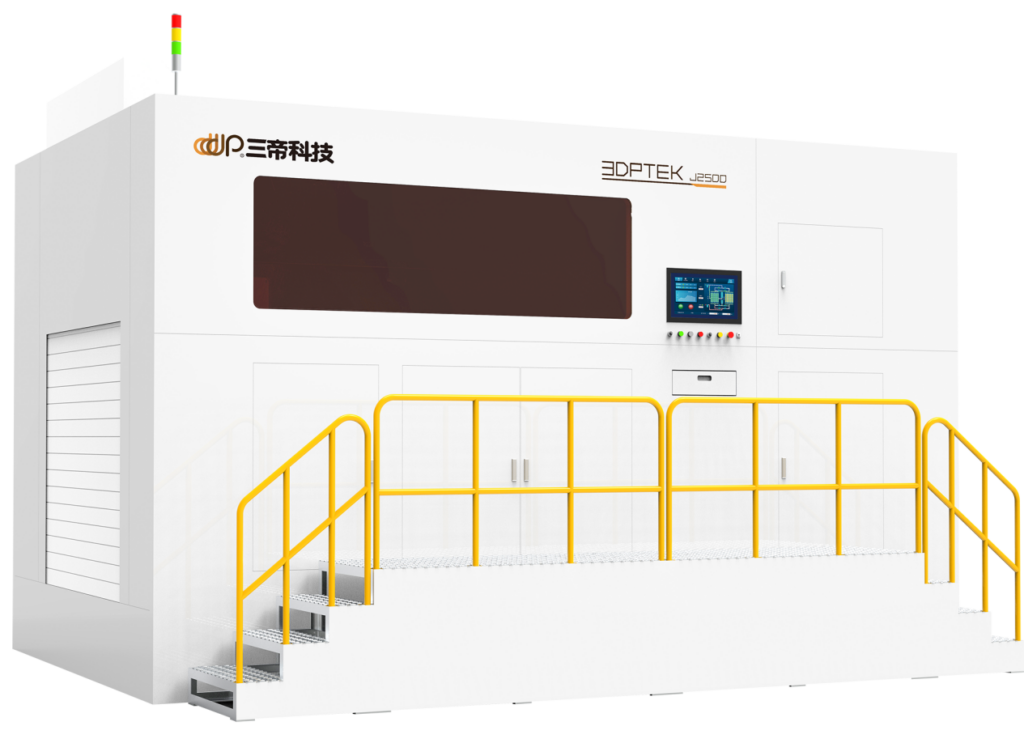

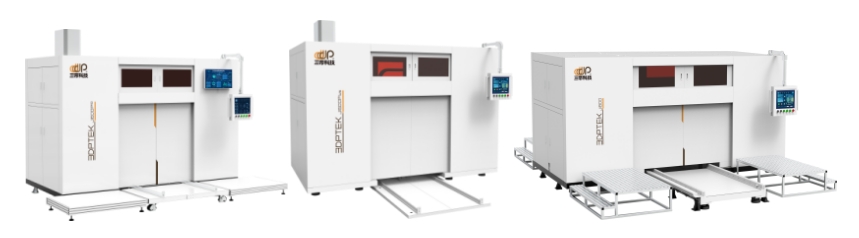

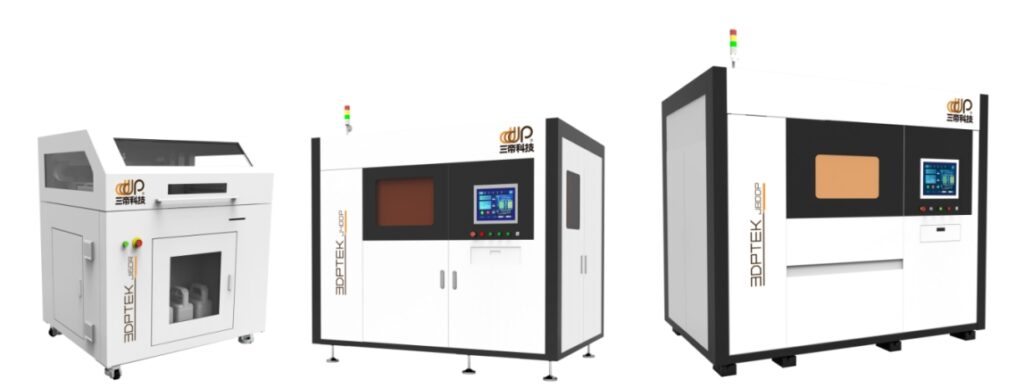

Figure: 1.6m, 1.8m, 2.5m, 4m 3DP Sand Printer

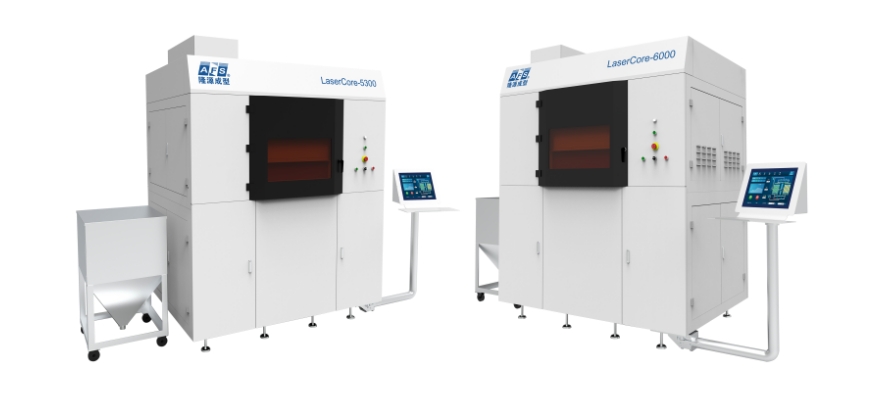

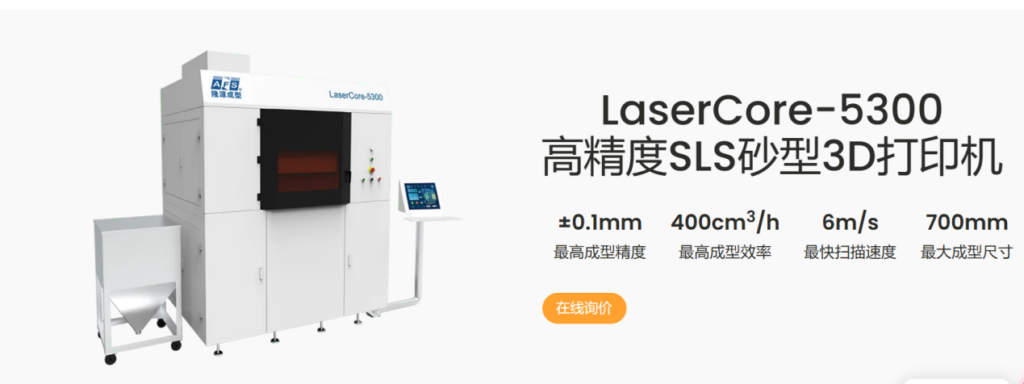

In addition, SANTI's self-developedSLS Selection Laser Sintering PrinterThe same outstanding performance. The sand pattern printed by this series of equipment is characterized by high precision and high strength, which is suitable for the manufacture of complex pipelines and oil pipeline structures. With stable and reliable operation, this series of equipment has provided solutions for more than a hundred domestic and foreign customers, and has been highly recognized.

Figure: LaserCore-5300/6000

Through the 3D casting factories and printing service centers in Xianyang, Shaanxi, Daiming, Hebei, Pingdingshan, Henan, Yulin, Guangxi, Rizhao, Shandong, Linzhou, Henan, Tongling, Anhui, etc., SANDI Technology has established the capability of full-size, multi-material, full-chain rapid manufacturing services, which can provide users in the fields of aerospace, electric power and energy, ships, pumps and valves, automobiles, rail transportation, construction machinery, etc., aluminum alloy, copper alloy, cast iron, aluminum alloy, copper alloy, cast iron, magnesium alloy, high-temperature alloy, titanium alloy and other materials, as well as casting sand, wax 3D printing services.

[About SANDI TECHNOLOGY

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national specialized, special and new "small giant" enterprise, and a typical application scenario supplier of additive manufacturing of the Ministry of Industry and Information Technology (MIIT). At the same time has laser and binder jet 3D printing equipment and materials technology and application process, business covers the development and production of 3D printing equipment, 3D printing raw materials development and production, 3D printing process technology support services, rapid finished parts manufacturing services, etc., the establishment of a complete 3D printing additive manufacturing industry chain, which is widely used in aerospace, electric power and energy, ships, pumps and valves, automobiles, rail transportation, industrial machinery, 3C electronics, rehabilitation and transportation, and industrial machinery, 3C electronics, and industrial machinery, and industrial machinery, and industrial machinery, and industrial machinery, and 3C electronics, and rehabilitation and transportation, industrial machinery, 3C electronics, rehabilitation and medical treatment, education and scientific research, sculpture and cultural creation and other fields.

In aerospace, automobile manufacturing, energy equipment and other fields, the production of large and complex castings has been a difficult problem. The traditional sand casting process has the disadvantages of long cycle time, high cost, insufficient precision, etc. It is also limited by mold development and manual operation. How to break through the technical bottleneck and realize efficient, accurate and green integrated manufacturing? SANDI Technology brings a new solution.

Breaking with tradition: 3DP sand printing technology for more freedom in manufacturing

SANDI Technology has independently developed and launched the3DPTEK - J2500 Sand PrinterIt adopts inkjet sand 3D printing technology, breaking the traditional process limitations, no mold development, digital moldless molding, molding size up to 2500×1500×1000mm, which can easily cope with the production needs of large and complex castings in the fields of aviation and aerospace, electric power and energy, ships, pumps and valves, and construction machinery.

highly accurate(math.) genusIntelligence to improve casting quality

High-precision printing: the use of precision motion control system and 400dpi ultra-fine printheads, precise control of multi-agency high-efficiency cooperative work, the highest printing accuracy ±0.3mm, reducing the traditional splicing process errors, to protect the complex structure of the integrated molding.

Advanced Technology Integration: Piezo inkjet technology + high resolution inkjet system + special binder to realize high speed large format accurate printing.

Automated process: from parameter setting to outputting finished products, the equipment can autonomously complete operations such as printing, testing and alarming, and support remote monitoring, the production process is safe and efficient, without manual guarding.

Efficient cost reduction(math.) genusPromoting Green Smart Manufacturing

Efficiency Improvement: Molding efficiency ≥ 210L/h, production efficiency is dozens of times of the traditional process, double working box design to further optimize the production capacity, to achieve 24-hour uninterrupted production.

Cost reduction: eliminating the cost and time of mold development, reducing material waste by 30%, reducing the burden of enterprise production.

Green Smart: Low energy consumption and low emission processes meet environmental requirements.

Wide range of application scenarios(math.) genusRealize unlimited design possibilities

Whether it is a shaped surface, an internal runner, or a complex structure with many holes, 3DPTEK - J2500 can handle it easily. Designers can get rid of the limitations of machining, with the help of 3D software to give full play to their creativity, and truly realize "what you think is what you get".

SANDY TECHNOLOGY 3D printing technology empowers casting

Enhance the ability of new product development: no metal molds, reduce the cost of new product development, shorten the production cycle; enhance the enterprise's ability to develop new products, new customers and the ability to grab orders for bulk orders.

Rapid delivery of small-lot products: Low-cost, high-efficiency production of small-lot products through 3D printing or a combination of 3D printing and traditional processes.

Reduce process validation risk: Reduce the risk of failure and mold repair time by validating the process before opening the metal mold.

Rapid Manufacturing of Metal Molds: Rapid manufacturing of metal molds through 3D casting process, shortening the manufacturing cycle and reducing the manufacturing cost by more than 20%.

Optimize the process, improve the technical level: meet the demand for lightweight, complex structure products, realize integrated molding, parts manufacturing into components manufacturing, to help casting enterprises to improve the technical level, increase the added value of products, and enhance the level of corporate profitability.

Improve material utilization: Improve casting material utilization and reduce resource consumption.

Enhance the corporate image and improve the production environment: reduce labor intensity and alleviate recruitment problems.

Why choose SANTI TECHNOLOGY?

Stable and reliable equipment, proven in the market: 30 years of experience in powder laying technology, stable and reliable equipment, proven in the market, some users have purchased 3D printers that have been successfully and stably running for more than 20 years.

Meanwhile, we have mastered the "3DP+SLS+BJ+SLM" process: we have the typical application scenario of additive manufacturing of the Ministry of Industry and Information Technology - "3DP+SLS" composite sand molding process.

Hands-on training, professional guidance: Provide comprehensive process guidance, equipment training, etc. through its multiple 3D manufacturing centers.

Nationwide after-sales service, timely response: Through its multiple 3D manufacturing centers to provide timely after-sales service nearby, to ensure rapid response.

Market synergy and resource sharing: help customers expand business opportunities and enhance market competitiveness.

The full-size 3DP casting sand and SLS casting sand/wax series of printers independently developed by SANDI Technology can meet the manufacturing needs of products of different sizes and materials, and help users maximize their productivity with lower unit costs and shorter delivery times.

Figure: 1.6m, 1.8m, 4m 3DP casting sand printers

Figure: SLS Casting Sand/Wax Printer

Equipment order hotline: 13811566237

SANDY TECHNOLOGY Booth: Hall S8, Booth A06

The 23rd China International Foundry Expo will be held on May 20, 2025 at the Tianjin National Convention and Exhibition Center (No. 888, Guozhan Avenue, Xianshuigu Town, Jinnan District, Tianjin), and Beijing SANDY Technology Co.

High-precision, large-size 3DP sand printer3DPTEK-J2500

3DPTEK-J2500 is an industrial-grade 3D casting sand printer launched by SANDI Technology, with a large-size molding capability of 2500×1500×1000mm and a high-precision printing capability of ±0.3mm, which is suitable for the manufacture of large castings in the fields of aviation and aerospace, electric power and energy, ships, pumps and valves, and automobiles. The equipment adopts piezoelectric inkjet printing technology, high-resolution inkjet system and special binder formula, which can realize integrated molding of complex structures and avoid the loss of precision of traditional splicing process. Through digital moldless molding technology, it effectively reduces mold development costs and waste emissions, improves casting efficiency and quality, and helps enterprises achieve cost reduction and efficiency and sustainable development. The equipment adopts high-end core components to ensure long-term stable operation.

Sandless Box Large Size 3DP Sand Printer 3DPTEK-J4000

The sandbox-free large-size 3DP sand mold printer 3DPTEK-J4000 launched by SANDI Technology provides an efficient, high-quality and low-cost solution for the manufacturing of ultra-large castings with its disruptive technology. The device adopts sandbox-free flexible area molding technology, breaking through the traditional process of design space limitations, support for local printing, the maximum molding of 4 meters of sand molding, large size, thin-walled, multi-dimensional curved surfaces and complex cavities (such as the spiral cooling waterway) casting integrated molding, and the selling price is very cost-effective. At the same time to provide open-source material process, can be adjusted for the user on demand, supporting high-performance resin binder, curing agent, cleaning agent, to ensure the quality and stability of molding, and further reduce the overall cost.

In order to meet the diversified market demands, SANDI has self-developed 3DP casting sand and SLS casting sand/wax series printers in full sizes from millimeter to meter, which help users maximize productivity with lower unit cost and shorter delivery time.

Figure: 3DP Casting Sand Printer

Figure: SLS Casting Sand/Wax Printer

3D Castingservice

Based on 30 years of 3D printing service and casting experience, SANDI Technology has established full-size, multi-material, and full-chain rapid manufacturing service capabilities through 3D casting factories and printing service centers in Xianyang, Shaanxi, Daiming, Hebei, Pingdingshan, Henan, Yulin, Guangxi, Rizhao, Shandong, Linzhou, Henan, and Tongling, Anhui, etc., and can provide rapid R&D trial production and batch production of finished metal parts made of aluminum alloy, copper alloy, cast iron, cast steel, magnesium alloy, high temperature alloy, and titanium alloy, as well as casting sand and wax 3-D casting service. It can provide users in the fields of aerospace, electric power, ship pump valve, automobile, rail transportation, construction machinery, etc. with rapid research and development of finished metal parts made of aluminum alloy, copper alloy, cast iron, cast steel, magnesium alloy, high-temperature alloy, titanium alloy and other materials for trial production and batch production, as well as casting sand and wax 3D printing services.

Contact: 13811566237

Website:www.3dptek.com

Address: Building 2, No.7 House, Jin Yi Street, Shunyi District, Beijing, China

[About SANDI TECHNOLOGY

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national specialized, special and new "small giant" enterprise, and a typical application scenario supplier of additive manufacturing of the Ministry of Industry and Information Technology (MIIT). At the same time has laser and binder jet 3D printing equipment and materials technology and application process, three emperor technology business covers the development and production of 3D printing equipment, 3D printing raw materials development and production, 3D printing process technology support services, rapid finished parts manufacturing services, etc., to establish a complete 3D printing additive manufacturing industry chain, widely used in aerospace, electric power and energy, ships, pumps and valves, automobiles, rail transportation, industrial machinery, 3C additive manufacturing typical application scenarios, the Ministry of Industry and Information Technology, and the company is a leading supplier of additive manufacturing, Railway transportation, industrial machinery, 3C electronics, rehabilitation and medical treatment, education and research, sculpture and cultural creation and other fields.

2024 Innovative Technologies and Products for the Global Foundry Industry

2024 National Foundry Equipment Innovation Award

Award-winning products

Recently, Beijing 3DPTEK Technology Co.Ultra-large 3DP Sand Printer 3DPTEK-J4000Successful completion of installation and commissioning, in line with factory acceptance standards, will be delivered soon.

Figure: 3DPTEK-J4000 printing site

The equipment can effectively solve the efficiency and cost problems of large-size sand casting, providing a new solution for the industry. Traditional process in the production of large-size castings, usually need to split casting and then welding, increasing the design cost and time cost, but also prone to welding defects. 3DPTEK-J4000 adopts no sand box flexible area molding technology, support for local printing, the maximum can be molded 4 meters of the sand mold, can be completed in one piece of casting of large-size, complex structural parts, greatly improving production efficiency and casting quality, to meet the large size, high precision sand casting application needs. It can greatly improve production efficiency and casting quality, and meet the application requirements of large-size and high-precision sand castings.

In addition, the company also has 1.6 meters, 1.8 meters, 2.5 meters and other 3DP sand printer program to choose from, to meet the needs of different sizes of sand printing; at the same time to provide open source material process, can be adjusted for the user on demand; supporting the high-performance resin binder, curing agent, cleaning agent, to ensure that the molding quality and stability.

Equipment order hotline: 13811566237

3DPTEK-J4000 is especially suitable for large-size and batch casting manufacturing needs in aerospace, marine, electric energy, construction machinery, automotive (new energy) and other fields. In the aerospace field, it can be used to manufacture engine parts, spacecraft structural components, power units and other important parts, effectively solve the problem of molding oversized, multi-dimensional surfaces, complex structure of the workpiece, in the small batch of large-size mold manufacturing as well as special industry mold iterative upgrading of research and development on the traditional manufacturing process can not be compared with the advantages. In the field of electric power and energy, it can be used for the manufacture of large-size pressure-resistant complex cavity structure parts, large-size thin-walled lightweight parts and so on. In the automotive field, it can realize the manufacture of large-size thin-walled motor shells with complex spiral cooling waterways, lightweight frames, and complex internal cavity structure shell cylinder/cylinder head.

[About SANDI TECHNOLOGY

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national "specialization, specialization and innovation" small giant enterprise, the Ministry of Industry and Information Technology additive manufacturing typical application scenarios. At the same time has laser and binder jet 3D printing equipment and materials technology and application process, business covers 3D printing equipment, raw materials development and production, 3D printing process technology support services, metal parts rapid manufacturing services, etc., to establish a complete 3D printing additive manufacturing industry chain, widely used in aerospace, ships, pumps and valves, automotive, electric power and energy, industrial machinery, rail transportation, 3C, electronics, education and research, sculpture, culture and creativity, and so on. electronics, education and scientific research, sculpture and cultural creation, rehabilitation and medical industries.

Beijing SANDI Technology Co., Ltd. specializes in 3D printing equipment and additive manufacturing services, is theNational Specialized, Specialized and New "Small Giant" Enterprises, Typical Application Scenario Supplier of Additive Manufacturing of MIITTheIt also owns laser and binder jet 3D printing equipment and material technology and application process, and the product technology is mainly used to empower the casting industry and MIM industry. The business covers R&D and production of 3D printing equipment, R&D and production of 3D printing raw materials, and 3D printing process technology support services,Rapid Prototyping Servicesetc., has established a complete 3D printing rapid manufacturing industry chain.(Hotline: Manager Han 13811566237)

SANDI's self-developed industrial casting field for the3DP Inkjet Sand 3D Printer, SLS Selective Laser Sintering Sand/Wax 3D PrinterThe company is a blend of theNearly 30 years of experience in powder laying technologyThe company can meet the needs of manufacturing products of different sizes and materials.The

3DP Inkjet Sand 3D Printer

SANDI Technology 3DP inkjet sand 3D printer molding size, high printing efficiency, sand precision and strength than the traditional process, suitable for large size, complex structure, small and medium batch sand rapid manufacturing.

Application Cases

SLS Selective Laser Sintered Sand 3D Printer

SANDI Technology SLS selective laser sintering sand 3D printer is suitable for one-piece molding of complex pipeline and oil pipeline structure sand mold. The precision of the printed sand mold can reach ±0.1mm and the strength can reach 4-6MPa.

SLS Selective Laser Sintering Wax 3D Printer

SANDI Technology SLS Selective Zone Laser Sintering Wax 3D Printer can rapidly mold large-size, thin-walled structure wax patterns with high molding precision and excellent surface quality.

SANDY Technology 3D printing technology empowers casting

Primary value:

1. Enhancement of new product development capabilities

-No need to open metal molds, reduce the cost of new product development and shorten the production cycle;

-Enhance the enterprise's ability to develop new products and new customers and grab orders for bulk orders.

2. Fast delivery of small quantities:

-Low-cost and high-efficiency production of small-lot products through 3D printing or a combination of 3D printing and traditional processes (outer mold: metal mold/wood mold; sand core: 3D printing).

3. Reduce process validation risk:

-Process validation before opening metal molds reduces risk of failure and mold repair time.

4. Rapid manufacturing of metal molds:

-Rapidly manufacture metal molds (aluminum molds, iron molds, etc.) through 3D casting process, which can shorten the manufacturing cycle of metal molds and reduce the manufacturing cost of 20% or more.

5. Optimize the process and improve the technical level:

-Satisfy the demand for lightweight, complex structural products, realize integrated molding, parts manufacturing into components manufacturing, help casting enterprises to enhance the level of technology, improve the added value of products, enhance the profitability of enterprises.

6. Improve material utilization:

-Improve casting material utilization and reduce resource consumption.

7. Enhance the corporate image and improve the production environment:

-Reduces labor intensity and eases recruitment challenges.

Collaborative Advantage:

As a leader and application promoter of 3D printing technology, SANDY TECH.Has received investment support from well-known funds such as Jinke Junchuang, Zhongjin Capital, Zhongke Haichuang and Become Capital.The

Industry Applications

Hotline: Manager Han 13811566237

In today's industrial manufacturing field, technological innovation is driving industrial upgrading at an unprecedented rate. Among them, binder jetting (BJ) technology, due to its advantages of moldless manufacturing, high efficiency, low cost, and large-size parts manufacturing, is changing the traditional production mode, and showing great potential for batch industrialization application, becoming a new quality of productivity empowering the traditional industry.

In recent years, BJ technology has grown rapidly with the enrichment of material systems and breakthroughs in technological processes. According to SmarTech's prediction, by 2030, the global output value of BJ technology can reach 54 billion U.S. dollars (about 350 billion yuan).BJ binder jet is a 3D printing technology based on the powder bed process and inkjet principle, and the printed prototype parts (green blanks) are used to complete binder removal and densification of the blanks by using the degreasing and sintering process of the MIM (metal injection molding) technology to obtain the final part. As a high-efficiency, low-cost 3D printing technology, BJ technology combines the freedom and efficiency advantages of 3D printing and is also compatible with the standardized material system of powder metallurgy. Thus, it can play an important role in enhancing the manufacturing capability of traditional powder metallurgy, reducing costs, accelerating the R&D cycle, and realizing the manufacturing of complex structures and large-size products.

Image from: Colibrium Additive / GKN Additive

International manufacturers are optimistic about the market potential of BJ technology and have entered the market.GE General Electric has been laying out BJ technology since 2016, after its Colibrium Additive launched the Series 3 metal binder jetting system. It cooperates with automobile manufacturers to produce lightweight and high-performance automotive parts and enhance the performance of the entire vehicle.HP HP launched HP Metal Jet technology in 2018 based on its thermal inkjet (TIJ) expertise and launched HP Metal Jet S100 metal printing solution four years later.GKN Additive adopts HP Metal Jet technology for automotive and industrial parts mass production, and MIM industry leader Parmatech uses HP Metal Jet technology for the manufacture of complex shaped precision surgical tools.

Figure: SANDY TECHNOLOGY BJ Metal/Ceramic Printer 3DPTEK-J160R, 3DPTEK-J400P/800P

As a large manufacturing country, China's market demand for BJ technology is more urgent. The leading domestic 3D printing equipment and rapid manufacturing service provider Beijing SANDI Technology Co., Ltd. independently masters the key technologies of BJ technology equipment, materials, processes, etc., and has mature technology and experience in small particle size powder placement, powder bed densification enhancement, high dimensional accuracy control, binder material system development, and degreasing sintering process. The company's self-developed 3DPTEK-J160R/J400P/J800P serialized binder jet printing equipment and its molding process integrates a precise feeding system, a high density powder laying system and a high-precision inkjet printing control system, which solves the key common technologies of small particle size and low mobility powder laying and molding density and breaks through the key technologies of high-resolution and high-precision inkjet control, and can realize 800-1200dpi high-resolution printing and molding, molding accuracy is better than ±0.1mm, molding efficiency up to 3600cc/h, the relevant technical indicators have reached the international advanced level.

Figure: BJ metal sample

SANDI Technology has gradually formed a sound binder material molding process system in years of BJ technology research. Based on more than 20 kinds of process formulas formed by two major types of water-based environmentally friendly binder and solvent-based high-efficiency binder, we have carried out systematic research and analysis on the physical and chemical properties of the binder and the interaction between the binder and the powder, and developed corresponding molding processes and post-processing processes such as degreasing and sintering, which have realized a complete and complete molding process applicable to stainless steel, tool steel, titanium alloys, copper alloys, high-temperature alloys, hard alloys and other metal materials, silicone carbide ( SiC) and other ceramic materials, as well as PMX crystalline wax, inorganic salts, food, pharmaceuticals, polymer composites and other non-metallic materials molding process. Meanwhile, through the systematic research on high density degreasing and sintering molding process, we have realized the shape and property control of metal and ceramic products in the process of degreasing and sintering, and realized the precise control of the quality of the finished products after degreasing and sintering, and the performance of the products is better than the mechanical properties of the MIM international material standard.

Figure: BJ ceramic sample

At the same time of realizing independent technological innovation, SANDI Technology gradually completes the construction of BJ standard manufacturing process, and establishes distributed printing service centers across the country to develop product manufacturing process based on BJ technology for customers, and promotes its application to the market. In addition, the company jointly with the Shenzhen Vocational and Technical University to build a joint laboratory of additive manufacturing technology, combined with Shenzhen Tsinghua University Research Institute, Shanghai Jiao Tong University, University of Science and Technology in Beijing and other research institutes and related teams to jointly carry out binder jet molding and other materials, process and application of basic technology research, and to promote the industrialization and application of the industrial molds, cutting tools, 3C electronic products, and complex, shaped and large-size ceramic products and other fields. Industrialization application.

In the field of 3C electronics, the market demand for increasingly diversified, complex and refined products has posed challenges to manufacturing technology, and traditional manufacturing technology has many limitations such as high manufacturing difficulty, low yield, high cost, etc., especially titanium alloys and other difficult-to-machine lightweight materials are even more difficult to realize. SANDI Technology has successfully broken through the traditional titanium alloy forming manufacturing technology barriers, based on BJ technology to achieve the rapid prototyping manufacturing of titanium alloy and other active metals, to realize the complex structure of 3C electronic product parts and components fast near-net shaping at the same time to simplify the manufacturing process and reduce the production and manufacturing costs.

Chart:Based on SANTI TechnologyautonomyBJskillfabrication(used form a nominal expression)Typical 3CProduct ComponentsMinimum structural scale 0.4mm, sintered densities better than 99%

In the field of food and drugs, in response to the growing demand for diversified, personalized and precise dietary markets, SANDI Technology, in conjunction with the Institute of Agricultural Products Processing of the Chinese Academy of Agricultural Sciences, carries out research on the adaptability of technology and equipment and equipment integration based on the self-developed BJ equipment, develops easy-to-swallow food made of food hydrogel and special shaped food made of food-based particles and carries out comprehensive evaluations of its safety and reliability. Comprehensive evaluation, and ultimately realize the industrialization demonstration application of personalized food additive manufacturing and intelligent processing equipment.

In the field of molds, for the problem of the difficulty of manufacturing molds with complex surfaces and fine texture structures, based on SANDI's BJ technology, it can realize the manufacturing of metal molds with high complexity and fineness in the scale range of 300mm×200mm×150mm, with the minimum texture expression scale of about 0.26-0.3mm, and at the same time, it breaks through the technology of sintering and densification of large-size atypical structural metal parts to realize At the same time, we have broken through the sintering densification technology for large-size non-typical structural metal parts, and realized the shape-controlled sintering with sintering performance meeting the requirements of practical applications.

With the continuous progress and innovation of technology, BJ technology is expected to play a more critical role in the future of industrial manufacturing, and its positive impact on manufacturing costs, efficiency and quality will certainly further promote this technology in 3C electronics, molds, automobiles, hardware, tools, cutting tools, medical equipment, sports equipment and other industries to form a hundred billion scale of industrialized applications.

[___About SANDI Technology]

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national "specialization, specialization and innovation" small giant enterprise, the Ministry of Industry and Information Technology additive manufacturing typical application scenarios supplier. At the same time has laser and binder jet 3D printing equipment and materials technology and application process, business covers 3D printing equipment, raw materials research and development and production, metal parts rapid manufacturing services, 3D printing process technology support services, etc., to establish a complete 3D printing additive manufacturing industry chain, widely used in aerospace, ship pumps and valves, automotive, energy power, industrial machinery, rail transportation, 3C, electronics, education and research, sculpture, culture and creativity. electronics, education and scientific research, sculpture and cultural creation, rehabilitation and medical industries.

In the process of global active response to climate change, towards sustainable development, the integration of 3D printing and casting for the green upgrade of China's foundry industry has brought a key opportunity, this change is closely linked to the dual-carbon goals, it is urgent to carry out systematic planning and promotion from the national policy level, especially combined with China's large foundry industry base and unique manufacturing cluster advantages.

Green casting sand mold made by △3DP sand printing process

Huge base of industry scale

China as a global casting country, has a strong basic industrial volume, there are more than 24,000 casting enterprises, casting production accounted for the world 45%. According to the China Foundry Association data, in 2023, China's total output of all types of castings 51.9 million tons. Such a large industrial scale, the formation and development of foundry industry clusters provide a solid foundation, the agglomeration of many enterprises has produced economies of scale, reducing production costs and improving production efficiency.

Complete industry chain support

The casting industry has a long industrial chain, covering upstream raw material suppliers and equipment suppliers, midstream casting enterprises, and downstream numerous application fields. China's foundry industry cluster within the enterprise division of labor is clear, close collaboration, the formation of a complete industrial chain supporting. For example, in Henan and other places in the foundry industry cluster, not only a large number of foundry enterprises, and the provision of pig iron, scrap steel and other raw material suppliers, as well as the production of foundry machinery, machining equipment, testing equipment, this complete industrial chain makes the transaction costs between enterprises to reduce the shortening of the production cycle to respond quickly to the market demand, and enhance the overall competitiveness of the cluster.

Rich technical and human resources

After years of development, China's foundry industry cluster has accumulated a wealth of technology and human resources. On the one hand, the cluster enterprises in the long-term production practice of continuous exploration and innovation, the formation of their respective core technologies and techniques, such as some areas in the sand casting, precision casting, die casting and other areas with unique technical advantages; On the other hand, the cluster attracted a large number of professionals, including skilled workers, engineers, researchers and so on, they provide intellectual support for the enterprise's technological research and development and innovation. At the same time, the talent flow and technical exchanges between enterprises in the cluster are also more frequent, promoting the dissemination of technology and innovation, and is conducive to enhancing the technical level of the cluster as a whole.

Strong market radiation capability

China's casting industry cluster is widely distributed, and mostly concentrated in economically developed, convenient transportation areas, such as the Yangtze River Delta, the Pearl River Delta, etc. These areas have a superior geographic location and a good market environment, able to radiate the national and even global markets. The Yangtze River Delta casting industry cluster, for example, the production of castings not only to meet the domestic automobile, machinery and equipment industries such as a large number of needs, but also exported to Europe and the United States, Southeast Asia and other international markets, a strong market radiation capacity for the development of industrial clusters provides a broad space, prompting the enterprise to continue to expand the scale of production, improve product quality and market share.

Policy support and industry guidance

The state attaches great importance to the development of the foundry industry, the introduction of a series of related policies, such as the "14th Five-Year Plan" in the foundry industry digital transformation and development of clear goals, including the use of 3D printing technology by 2025 to produce more than 500,000 tons of castings, and so on. These policies provide strong support for the development of foundry industry clusters, guiding the development of industry clusters to high-end, intelligent, green direction, promoting the optimization and upgrading of industrial structure, and enhance the overall competitiveness of the cluster.

Regional brand effect

Some well-known foundry industry clusters have formed a regional brand effect, such as Botou's "China Foundry City", Jiaozuo's cylinder liner, "Henshan Casting", "Linzhou Casting" and so on. These regional brands have a high degree of visibility and reputation in the market, to attract more customers and resources for the cluster enterprises to bring more opportunities for development. At the same time, the construction of regional brands also prompted enterprises to pay more attention to product quality and brand image, strengthened cooperation and self-discipline among enterprises, and is conducive to maintaining the overall interests of the cluster and the market order.

China's foundry enterprises all over the world, forming a number of distinctive characteristics of China's manufacturing clusters. For example, in Henan Province, Xinxiang City has an annual output of 55,000 tons of large cast steel parts, with an export volume of more than 30%, Hui County has more than 100 casting enterprises, with a production capacity of more than 1.3 million tons; Pingdingshan Jiaxian is known as the capital of China's cast-iron pots ......

These clusters in the long-term development process, has accumulated a wealth of production experience and industrial resources, but at the same time also faced with the traditional casting process brought about by high energy consumption, high pollution and waste of resources and other issues. According to statistics, the traditional casting process in the material utilization rate there is greater room for improvement, and energy consumption intensity is higher, which not only increases the production cost of enterprises, but also on the environment has caused greater pressure, and China's dual-carbon goals to achieve a certain contradiction .

3D printing + casting new quality productivity

From the perspective of efficiency, pollution reduction and cost reduction, 3D printing + casting has green attributes and advanced nature:

improve efficiency

- Significantly shorten the production cycle: a company using "3D +" casting process, the production cycle shortened by 60% or more, such as core compressor cylinder production cycle shortened from 48 days to 12 days, the L-shaped bed shortened from 45 days to 15 days.

- Significant increase in capacity: "3D+" casting process capacity increase of 50%, doubling the efficiency, can quickly respond to market demand, improve the competitiveness of enterprises.

- Rapid prototyping: sand 3D printing technology can produce complex sand patterns in a short period of time, and quickly complete the production of prototype parts, such as a new energy vehicle enterprises trial production of water-cooled motor shells for commercial trucks, the use of 3DP sand printing delivered in 10 days, compared with the traditional process of 60 days of the production cycle has been shortened by 83%.

pollution reduction

- Material waste reduction: 3D printing on-demand manufacturing, support sand online recycling, sand utilization rate up to 95% or more, reducing the waste of raw materials in the traditional mold making process.

- Dust pollution reduction: SANDI technology sand 3D printing equipment in the production process can effectively reduce the generation of dust, with recycled sand and other environmentally friendly materials, help foundries to realize green manufacturing.

reduce costs

- Mould cost reduction: In traditional casting, the cost of instrument panel mould is 700,000-1,000,000 RMB, bumper mould is 350,000-700,000 RMB, and engine parts mould is 150,000-600,000 RMB or even higher, while 3D printing sand mould is low cost, flexible in design modification, and does not require expensive mould manufacturing cost.

- Reduced labor costs: The automation of the 3D printing process reduces the reliance on manual operation and human error, reducing labor costs, such as the 3D printing equipment of SANDI Technology can be operated with only simple training, without the need for a large number of manpower synergies.

- Reduced energy consumption: 3DP printing process 3D printing technology consumes less energy than sand core manufacturing and injection molding equipment. Compared with injection molding, 3DP printing sand molding is through the nozzle spray binder will sand bonding molding, without the need for injection molding like the material for a long time heating and melting and other processes, so the energy consumption is greatly reduced. Compared with 3DP printing sand mold, traditional sand core manufacturing in the hot core box method core, need to make the core box to keep at 200 ℃ -300 ℃, let the core sand shot into the core box, ammonium chloride in the higher temperature and the resin in the free formaldehyde reaction to generate acid, so that the core hardened very quickly, the process of energy consumption. While 3DP printing sand mold process, the sand does not need to be heated to such a high temperature, and the equipment itself is relatively low energy consumption.

△Green fast casting plant after upgrading 3DP sand printing process

SANTI Technology helps 3D casting

In this context.3D Printing Technology, Inc.The exploration and practice of the industry provides useful reference for the development of the industry. Three Emperor Technology has achieved remarkable results by acquiring six traditional foundries and introducing 3D printing technology to promote their transformation and upgrading. In the production process, the precise characteristics of 3D printing technology greatly improves the utilization rate of materials, effectively reduces the carbon emissions from the mining of raw materials to the processing of each link, reduces the impact on the environment, which is an important demonstration of China's foundry industry to reduce the intensity of resource consumption, improve the efficiency of resource utilization, and the relevant departments of the state to promote the green development of the industry, optimize the industrial structure of the policy direction of a high degree of compatibility.

Analyzed from the perspective of energy consumption, the repeated processing and correction processes in the traditional casting process lead to high energy consumption, while 3D printing-assisted casting simplifies the production process and reduces energy demand. The country has been committed to the reform and development of the energy sector, introduced a series of policy measures to improve energy efficiency and promote the application of clean energy. Foundry enterprises using 3D printing technology, can better synergize with these energy policies, such as the introduction of energy-saving 3D printing casting equipment, and combined with clean energy power supply, to further reduce carbon emissions, help the foundry industry green optimization of the energy structure, for the realization of the dual-carbon goals of total energy consumption and intensity of "double control" play a positive role. Role.

In the promotion of technological innovation, the development of China's manufacturing industry can not be separated from the depth of the application of emerging technologies in traditional industries and integration of innovation. State in the "14th Five-Year Plan" period, the Ministry of Industry and Information Technology and other departments have issued "on the promotion of casting and forging industry high-quality development of the guiding opinions" for the development of the industry to point out the direction of the industry, such as the promotion of intelligent transformation, to create intelligent manufacturing demonstration factories; to help the green development, adjusting the production capacity replacement policy; to support the development of high-quality enterprises, cultivate specialties, specialties, new "small giants" and manufacturing single champion; the development of industrial clusters, cultivate casting characteristics of industrial clusters and so on. For 3D printing + casting this innovative model, the relevant state departments attach great importance to the R & D investment, personnel training and technology promotion and other aspects of increasing policy support, continuation and deepening of the "14th Five-Year Plan" development strategy to the "15th Five-Year Plan" and beyond. Stage. Through the establishment of a special R & D fund to encourage universities, research institutions and enterprises to carry out in-depth cooperation between industry, academia and research, and jointly overcome technical problems, accelerate the maturity of green casting technology and application of popularization, enhance the overall technical level of China's foundry industry, enhance the low-carbon competitiveness in the international market, drive the high-quality development of industry with technological innovation, and to realize the transformation from a large casting country to a strong casting country, and specialize in specialties and special new technologies. The practical achievements of "small giants" SANDI Technology also provide a realistic reference for the precise implementation and optimization of the policy.

From the perspective of industrial cluster development, the relevant state departments can give full play to the advantages of China's manufacturing clusters to guide the establishment of 3D printing + casting green industrial park. Based on the foundry purchased by SanDi Technology and the industrial cluster where it is located, attract upstream and downstream related enterprises to move into the park, forming a complete green industry chain ecology. In the park, we centrally configure perfect infrastructure and environmental protection facilities, realize centralized waste treatment and recycling, and build a closed loop of green industry chain. Enterprises share 3D printing technology resources, energy management system, etc., can effectively reduce overall operating costs and carbon emissions, while facilitating the unified supervision and promotion of green casting standards, promote the green and low-carbon synergistic development of enterprises within the cluster, to become a demonstration sample of the green transformation of China's traditional foundry industry under the dual-carbon goal, to promote the comprehensive green change of the national foundry industry, and to realize the carbon peak and carbon neutrality goals for China. Carbon peak, carbon neutral target to provide solid industrial support and strong policy practice examples, and further highlight China's leading position in the field of global green manufacturing and the role of great powers.

Recently, Yunnan South Asia Southeast Asia Security Research Center ("Yunnan South Asia Southeast Asia Security Research Center"), Yunnan Cross-border Data Technology Development Co,Beijing SANDI Technology Co.("SANDI") officially signed a strategic cooperation framework agreement on additive manufacturing foreign data security, the three parties will focus on Yunnan Dianzhong New Area in digital additive manufacturing, 3D printing foreign data, foreign data talent training and research, 3D printing foreign data security certification and other in-depth cooperation.

China has made remarkable progress in the field of additive manufacturing, especially in terms of exports, and has become one of the world's major suppliers of additive manufacturing products and services. However, with the development of technology and the intensification of international competition, foreign-related data security has become an important issue. In the context of globalization, countries need to protect key technologies and data security as well as promote international cooperation and technological innovation. By establishing multilateral mechanisms and international standards, cross-border data flows can be better managed to ensure the healthy development of additive manufacturing technologies.

The signing of the strategic cooperation between Yunnan South Asia Southeast Asia An Research Center, Yunnan Cross-border Digital Technology and SANTI Technology is an important initiative of the three parties to promote the development of Yunnan Province into a key node of China's radiation center facing South Asia Southeast Asia, an important economic driver for the construction of Yunnan Bridgehead, a model region for the experiment of the comprehensive construction of new urbanization in the western region and an advanced demonstration zone for reform and innovation, in accordance with the principles of complementarity of strengths and resources, synergistic development, and mutual benefit. It is an important initiative to develop Yunnan Province into a key node of China's radiation center facing South Asia and Southeast Asia, an important economic driving force for the construction of Yunnan Bridgehead, a model region for the comprehensive experiment on the construction of a new type of urbanization in the western region, and an early demonstration zone for reform and innovation.

Yunnan Security Research Center for South and Southeast Asia mainly carries out research on topics related to national security and overseas interest protection for South and Southeast Asia, analysis and research on security of security information technology products and systems, research on SWSJ security policies, standards, technologies and assessment methods, research and development of information technology and cybersecurity technologies, research and consulting services for planning industrial security projects and topics.

Based in Yunnan and facing the whole country, Yunnan Cross-border Data Technology Development Co., Ltd. is committed to promoting the development of foreign-related data security applications, and providing safe and efficient foreign-related data security services for the global operation of China's industries and enterprises, the national Belt and Road and the construction of Yunnan Digital Economy Demonstration Zone facing South Asia and Southeast Asia. By guaranteeing the safe implementation of the national strategy for South Asia and Southeast Asia, it realizes the effective protection of the overseas interests of the country, industries and enterprises.

Ltd. is a leading provider of 3D printing equipment and rapid manufacturing services, business covers 3D printing equipment, raw materials, R & D and production, rapid manufacturing services for finished metal parts, 3D printing process technology support services, etc., which are widely used in aerospace, ship pumps and valves, automotive, energy power, industrial machinery, rail transportation, 3C electronics, education and research, sculpture and cultural and creative, Rehabilitation and medical industries.